You climb into your truck on a sweltering summer day, crank the AC, and within minutes, you’re comfortable despite the blazing heat outside. But have you ever wondered how that happens?

Understanding how your truck’s air conditioning system works helps you maintain it properly and diagnose problems when it’s not blowing cold. Let’s break down this vital system step by step.

The Basic Principle of Air Conditioning

Before diving into specific components, let’s understand the basic physics behind every air conditioner.

Truck AC systems don’t actually “make cold air.” Instead, they remove heat from your cab’s air and release it outside.

Heat Transfer and the Refrigeration Cycle

Air conditioning relies on the unique properties of refrigerant — a compound that easily changes between liquid and gas.

- When refrigerant evaporates, it absorbs heat from its surroundings.

- When it condenses, it releases that heat.

Your truck’s AC system continually cycles refrigerant through this process. It evaporates inside your cab, absorbing heat and cooling the air, then condenses outside, releasing the heat into the atmosphere. The system runs in a loop, transferring heat from inside your cab to the outdoors.

Pressure and Temperature Relationship

This process also depends on the link between pressure and temperature.

- At low pressure, the refrigerant evaporates at a very low temperature (cooling inside the cab).

- At high pressure, it condenses at a higher temperature (releasing heat outside).

By regulating pressure, the system determines where refrigerant absorbs or expels heat — all based on solid thermodynamics, not magic.

At FridayParts, we’ve seen these same principles at work across all kinds of trucks — from light‑duty pickups to long‑haul rigs and heavy dump trucks.

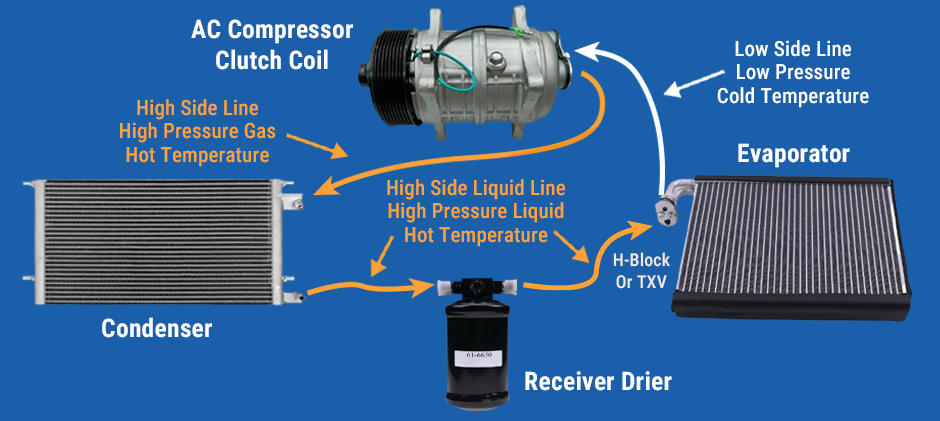

Key Components of a Truck’s AC System

Your truck’s air conditioning setup has several interconnected parts. Each one plays a specific role in keeping your cab cool.

Compressor

The compressor, driven by the engine’s belt or an electric clutch, compresses low‑pressure refrigerant vapor from the evaporator into high‑pressure vapor and pumps it through the system.

- Function: Increases pressure and circulates refrigerant

- Location: Engine compartment, belt‑driven

- Common Issues: Clutch failure, internal wear, leaks

Condenser

Mounted in front of your truck’s radiator, the condenser acts like a heat exchanger. Hot, high‑pressure vapor from the compressor flows through it. Air moving across its fins carries away heat, turning the vapor into a high‑pressure liquid.

- Function: Releases heat to the outside air

- Location: Front of truck, in front of radiator

- Common Issues: Leaks, clogging, damage from debris or road salts

Expansion Valve or Orifice Tube

This expansion valve is the system’s control valve — separating the high‑pressure and low‑pressure sides.

As high‑pressure liquid refrigerant passes through it, pressure drops dramatically. This sudden drop makes part of the refrigerant vaporize and become very cold before entering the evaporator.

- Function: Controls refrigerant flow and pressure drop

- Location: Between the condenser and the evaporator

- Common Issues: Blockage, ice formation, faulty metering

Evaporator

Located behind your truck’s dashboard, the evaporator allows the cold refrigerant to absorb heat from the cab’s air. A blower fan pushes warm cabin air over the evaporator’s cold fins — cooling and dehumidifying it before sending it through the vents.

- Function: Absorbs heat from the cab air

- Location: Inside dashboard HVAC housing

- Common Issues: Leaks, dust buildup, mold, or odor formation

Receiver‑Drier or Accumulator

These serve as filters, reservoirs, and moisture removers. The receiver‑drier (used with expansion valve systems) or accumulator (used with orifice tube systems) traps moisture and debris that could damage the system.

- Function: Stores refrigerant, removes moisture, filters contaminants

- Location: Near condenser or evaporator

- Common Issues: Desiccant saturation, clogging

Component Summary

| Component | Function | Location | Common Issues |

|---|---|---|---|

| Compressor | Pressurizes the refrigerant, pumps it through the system | Engine bay | Clutch or internal wear, leaks |

| Condenser | Dissipates heat to the outside air | Front of the truck | Debris blockage, leaks |

| Expansion Valve / Orifice Tube | Creates pressure drop, controls flow | Lines between condenser & evaporator | Clogging, freezing |

| Evaporator | Absorbs cab heat | Behind dashboard | Mold, odor, leaks |

| Receiver‑Drier / Accumulator | Filters & removes moisture | Near condenser/evaporator | Desiccant saturation, clogging |

The Complete AC Cycle Step‑by‑Step

Let’s trace the refrigerant as it moves through your truck’s system:

- Compression: Low‑pressure gas (around 30 PSI, 40°F) enters the compressor. It’s squeezed to 200–350 PSI and 150–170°F, then sent to the condenser.

- Condensation: The hot vapor passes through the condenser, releasing heat to the outside air until it becomes a high‑pressure liquid (100–120°F).

- Expansion: The expansion valve/orifice tube drops the liquid’s pressure to ≈ 30 PSI, causing it to partially evaporate and cool to 32–40°F.

- Evaporation: In the evaporator, this cold refrigerant absorbs heat from cab air. Air at 75–90°F is cooled to 45–55°F before it circulates back into the cab.

- Return: The warmed refrigerant vapor flows back to the compressor, repeating the cycle continuously.

Additional Truck AC Components

- Blower Motor & Fan: Circulates cooled air through vents.

- Condenser Fan: Provides extra airflow during idling or low‑speed driving.

- Pressure Switches: Shut off the compressor if refrigerant pressure is too low or high.

- Temperature Sensors: Prevent evaporator freeze‑up.

- Blend Doors & Climate Controls: Mix hot and cold air to regulate cabin temperature.

- Refrigerant Lines: Metal and rubber hoses transport refrigerant between components — all must be tightly sealed.

Common Truck AC Problems and Symptoms

| Symptom | Possible Cause |

|---|---|

| No Cold Air | Low refrigerant charge, failed compressor, blocked expansion valve |

| Weak Cooling | Partially clogged condenser, worn belt, low refrigerant, dirty filter |

| AC Blows Cold Then Warm | Evaporator freeze‑up or low refrigerant |

| Strange Noises | Squealing belt, worn compressor bearing, hissing leak |

| Bad Odors | Mold on the evaporator or a dirty cabin filter |

| Water in Cab | Clogged evaporator drain line |

Truck AC Maintenance Tips

- Run Your AC Regularly – Even in winter. Keeps compressor seals lubricated.

- Check Refrigerant Levels – If cooling weakens, check for leaks before topping up.

- Clean the Condenser – Road debris and bugs block airflow; rinse gently with water.

- Replace Cabin Air Filter – Restriction reduces system efficiency.

- Inspect Belts – Cracked or slipping belts cause compressor failure.

- Fix Issues Early – Small leaks or noises can lead to costly repairs later.

At FridayParts, we stock high‑quality compressors, condensers, hoses, and blower motors for all truck makes — keeping your fleet cool and operational through every season.

Refrigerants Differences

Your truck’s system depends on the right refrigerant and oil combination.

- R‑134a: The standard refrigerant used since the mid‑1990s — reliable and widely compatible.

- R‑1234yf: The new eco‑friendly alternative with lower global warming potential.

R‑134a and R‑1234yf require distinct lubricants (types of PAG oil). Always confirm compatibility and service specifications for your truck model.

Truck AC FAQs

Q: Why does my truck’s AC blow cold, then warm?

A: Usually due to evaporator freeze‑up or low refrigerant pressure.

Q: How much does it cost to recharge the truck’s AC?

A: Typically $100‑$200 if no leaks exist. Leak detection or component replacement can add $150‑$800.

Q: Can I recharge the system myself?

A: DIY recharge kits risk overcharging or introducing contaminants. Professional servicing ensures proper vacuum and charge procedure.

Q: Why does my AC smell bad?

A: Moisture and mold build up on the evaporator. Clean it and replace the cabin filter.

Q: How long should a truck’s AC last?

A: With maintenance, most compressors last 8–15 years. Condensers and evaporators can last even longer if not damaged.

Final Thoughts

Your truck’s air conditioning system is a true feat of engineering — a compact, durable, and efficient setup designed to handle intense heat, vibration, and workload. Understanding how the system operates helps you perform smarter maintenance, recognize early warning signs, and prevent downtime.

Keep your truck’s AC running strong season after season with quality replacement parts and expert support from FridayParts — your reliable source for truck climate control components.