If you’ve ever wondered what keeps your diesel engine from going into overdrive and potentially self-destructing, the answer is pretty simple – it’s all about the wastegate. This small but mighty component plays a huge role in how your turbo performs. At FridayParts, we know that understanding your diesel engine parts isn’t just good-to-know info – it’s essential for keeping your machine running at its best. Let’s dive into the world of engine wastegates and discover how they work, why they matter, and how to spot when they’re not doing their job right.

What Is a Wastegate in a Diesel Turbo System?

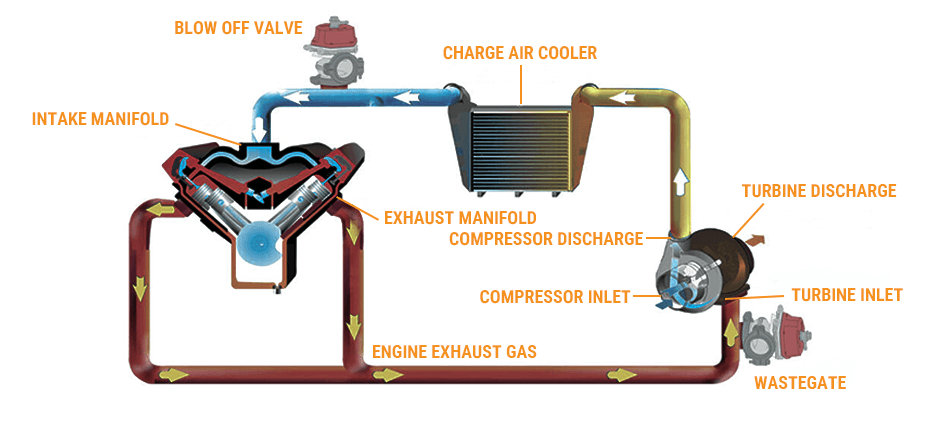

A wastegate is basically a valve that controls the exhaust gas flow to your turbo. Think of it as a traffic cop for your engine’s exhaust system. When your engine is working hard and creating a lot of exhaust, the wastegate helps direct some of that gas away from the turbine wheel.

Without getting too technical, the wastegate’s main job is to limit how fast your turbocharger spins. It does this by “wasting” some of the exhaust gas by routing it around the turbo instead of through it. This might sound counterproductive, but trust us – it’s actually protecting your engine from too much boost pressure.

Engine wastegates come in two main types: internal wastegates that are built into the turbo housing, and external wastegates that are separate components. Both do the same basic job, but they’re set up differently depending on your engine’s design and performance needs.

The Basic Working Principle of a Diesel Turbo Wastegate

Here’s how a wastegate works in simple terms: when your diesel engine is running, exhaust gases spin the turbo’s turbine wheel, which then spins the compressor wheel. The compressor wheel forces more air into your engine, which means more fuel can be burned, creating more power.

But there’s a catch – if the turbo spins too fast, it creates too much boost pressure, which can damage your engine. That’s where the wastegate steps in.

The wastegate uses a pressure-sensing system connected to a spring-loaded valve. When the boost pressure reaches a certain level, it pushes against the spring, opening the valve. This lets some exhaust gas bypass the turbine wheel, effectively slowing down the turbo and limiting the boost pressure.

It’s a brilliantly simple solution to a complex problem. The wastegate constantly adjusts based on real-time engine conditions, opening more when pressure gets too high and closing when more boost is needed.

Internal vs. External Wastegates: What’s the Difference?

When we talk about engine wastegates for diesel turbos, there are two main types you’ll come across: internal and external. Each has its own pros and cons, and the right choice depends on your specific engine setup and performance goals.

Internal engine wastegates are built right into the turbocharger housing. They’re compact, simple, and come standard on many factory turbo setups. The valve is controlled by a small actuator mounted directly to the turbo housing. When boost pressure reaches the set limit, the actuator opens the valve, allowing exhaust to bypass the turbine wheel.

The big advantage here is simplicity – there’s no need for extra plumbing or components. They’re also typically more than adequate for stock or mildly modified engines. However, they do have limitations when it comes to high-performance applications.

External engine wastegates, on the other hand, are separate components mounted on the exhaust manifold. They’re larger, more adjustable, and can handle higher exhaust flow rates. This makes them ideal for high-performance applications where precise boost control is critical.

With an external wastegate, you get more flexibility in terms of sizing and placement. You can choose a wastegate that’s perfectly matched to your performance goals. The downside? They’re more complex to install, require additional plumbing, and are generally more expensive.

Signs of a Failing Wastegate in Your Diesel Turbo

Like any mechanical component, wastegates can wear out or fail over time. Recognizing the warning signs early can save you from more serious (and expensive) engine problems down the road.

One of the most common symptoms of a failing wastegate is inconsistent boost pressure. You might notice your engine’s power delivery becomes erratic, with the boost either not building properly or spiking to unsafe levels. This often feels like the engine is surging or hesitating under acceleration.

Another red flag is a rattling or buzzing noise coming from the turbo area, especially under load. This could indicate that the wastegate valve is loose or not seating properly. In some cases, you might even hear a distinct hissing sound when the wastegate should be closed.

Black smoke from the exhaust can also point to wastegate issues. If the wastegate is stuck open, your turbo won’t build enough boost, leading to an improper air-fuel ratio and incomplete combustion.

On the flip side, if your wastegate is stuck closed, you might experience over-boosting. This can trigger your engine’s limp mode or even cause serious engine damage if left unchecked. Modern engines will usually have safeguards in place, but these aren’t foolproof.

Regular inspection of your wastegate actuator and linkage can help catch problems before they lead to performance issues or damage. Look for signs of wear, heat damage, or loose connections.

How Wastegates Protect Your Diesel Engine from Damage

Wastegates aren’t just performance components – they’re critical safety devices for your diesel engine. Without a properly functioning wastegate, your turbo could spin too fast, creating excessive boost pressure that might lead to catastrophic engine failure.

Here’s how wastegates protect your engine:

- Preventing over-boost conditions: By limiting boost pressure, wastegates keep your engine operating within safe parameters. This protects internal components like pistons, connecting rods, and head gaskets from excessive forces.

- Controlling exhaust gas temperatures: When boost is limited, exhaust gas temperatures are also kept in check. This helps prevent thermal damage to turbo components and exhaust valves.

- Reducing stress on the turbocharger: By regulating the turbine speed, wastegates help extend the life of your turbo’s bearings and other components that could wear prematurely under extreme conditions.

- Maintaining proper air-fuel ratios: Consistent boost control helps ensure your engine maintains the correct air-fuel mixture, which is essential for efficient combustion and emissions control.

Think of your wastegate as cheap insurance against expensive engine repairs. A properly functioning wastegate might cost a few hundred dollars to replace, but the engine damage it prevents could run into the thousands.

Wastegate Adjustments and Tuning for Optimal Performance

One of the cool things about wastegates is that they can often be adjusted to fine-tune your engine’s performance. This is especially true for external wastegates, which typically offer more adjustment options than their internal counterparts.

The most basic adjustment is spring pressure. By changing the spring in the wastegate actuator, you can alter the boost pressure at which the wastegate begins to open. Stiffer springs result in higher boost before the gate opens, while softer springs lower the threshold.

For more precise control, many modern diesel engines use electronic wastegate control through the engine management system. This allows for dynamic adjustments based on various engine parameters like RPM, load, temperature, and even gear position in some cases.

If you’re considering adjusting your wastegate for more performance, here are some tips:

- Start conservative – small changes can make big differences in boost pressure

- Always monitor boost with a reliable gauge when making adjustments

- Consider other supporting modifications your engine might need to handle increased boost

- On modern engines, professional tuning with diagnostic equipment is often the safest approach

Remember that more boost isn’t always better. Your engine has limits, and pushing beyond them without proper supporting modifications can lead to reduced reliability or even catastrophic failure.

Maintaining Your Diesel Turbo Wastegate for Longevity

Proper maintenance can significantly extend the life of your wastegate and turbocharger system. The good news is that wastegates are relatively simple devices that don’t require much maintenance, but there are still some important things to keep in mind.

First and foremost, regular oil changes with the correct oil specification are critical. Your turbocharger’s bearings rely on clean oil for lubrication, and the wastegate mechanism can be affected by oil contamination or sludge buildup.

For external wastegates, periodic inspection of the actuator, linkage, and valve is recommended. Look for signs of heat damage, worn pivot points, or weak spring tension. A quick visual check during other maintenance can catch potential issues early.

If your diesel has an internal wastegate, check for smooth operation of the actuator arm. Any sticking or binding could indicate problems that need attention. Carbon buildup can sometimes cause wastegate issues, especially in engines that see a lot of short trips or idle time.

It’s also a good idea to periodically check all vacuum or pressure lines connected to the wastegate actuator. Cracked or leaking lines can cause erratic boost control and poor performance.

Finally, always allow your engine to idle for at least 30 seconds before shutting down after hard driving. This simple habit helps cool the turbo and prevents oil coking, which can affect wastegate operation over time.

Is It Worth It?

If you’re looking to squeeze more performance from your diesel engine, you might be wondering if upgrading your wastegate is a worthwhile investment. The answer depends largely on your performance goals and current setup.

For most stock or mildly modified engines, the factory wastegate is perfectly adequate. It’s designed to work with your specific turbo and engine combination, providing reliable boost control for normal driving conditions.

However, if you’ve made significant power upgrades, an improved wastegate might be necessary. Here are some scenarios where an upgrade makes sense:

- You’ve installed a larger turbocharger that flows more exhaust gas than the stock wastegate can handle

- You’re running significantly higher boost levels than stock

- You need more precise boost control for competition or specialized applications

- Your stock wastegate has shown signs of weakness or inconsistency

Upgrading to a quality external wastegate can provide better boost control, more adjustment options, and greater durability under extreme conditions. Brands like Tial, Turbosmart, and Precision Turbo offer excellent options for serious performance applications.

Just remember that upgrading your wastegate often requires other supporting modifications. You’ll need proper mounting, exhaust plumbing, and usually professional tuning to make the most of the upgrade.

Common Wastegate Problems and How to Fix Them

Even the best-designed wastegates can develop issues over time. Knowing what to look for and how to address common problems can save you time, money, and frustration.

One of the most frequent issues is a wastegate that sticks or binds. This can happen due to carbon buildup, heat distortion, or simple wear and tear. The fix depends on the specific cause, but often involves cleaning, lubricating, or replacing worn components.

Leaking wastegates are another common problem. If the wastegate valve doesn’t seal properly when closed, exhaust gas escapes past the turbine wheel, reducing boost and performance. This often manifests as an inability to reach target boost pressure. In most cases, a leaking wastegate requires replacement of the valve or entire wastegate assembly.

Wastegate actuator failures can also occur. The diaphragm inside the actuator can tear, or the spring can weaken over time. If you notice an inconsistent boost or a rattle from the actuator, it may be time for a replacement.

For internal wastegates, the linkage between the actuator and valve can wear or become misadjusted. Sometimes a simple adjustment can restore proper operation, but in other cases, replacement parts may be needed.

If you’re experiencing any of these issues, don’t wait until they cause bigger problems. At FridayParts, we offer quality replacement wastegates and components to keep your diesel turbo performing at its best.

FAQs About Diesel Turbo Wastegates

Can I drive with a bad wastegate?

While you might be able to drive with a malfunctioning wastegate in the short term, it’s not recommended. A bad wastegate can lead to inconsistent performance, poor fuel economy, and in worst-case scenarios, serious engine or turbocharger damage. It’s best to address wastegate issues promptly.

How much does it cost to replace a diesel turbo wastegate?

Replacement costs vary widely depending on your vehicle and whether you have an internal or external wastegate. Internal wastegate repairs often require turbocharger service or replacement ($800-$2,500), while external wastegate replacement might range from $200-$800 for parts and labor. High-performance upgrades can cost significantly more.

How often should a wastegate be replaced?

There’s no set replacement interval for wastegates. They’re designed to last the life of the turbocharger in many cases. However, high-performance applications, extreme operating conditions, or manufacturing defects can shorten their lifespan. Regular inspection and addressing issues promptly is the best approach.

Can I adjust my wastegate myself for more boost?

While basic wastegate adjustments are possible for mechanically inclined owners, we recommend professional tuning for most modern diesel engines. Improper adjustments can lead to engine damage. If you do adjust it yourself, always use a reliable boost gauge and make small, incremental changes while monitoring engine performance carefully.