The Ford 3000 tractor, produced throughout the 1960s and 1970s, earned a reputation for its simple, durable design. But even the most reliable machines face age-related problems after decades of use. In this guide, we’ve gathered the most common Ford 3000 tractor questions from real owners on forums and farming communities, and provided clear, detailed answers to help you keep your tractor running smoothly. You’ll also find practical Ford 3000 maintenance tips to extend its life, avoid costly repairs, and get the most from your machine in this article.

About the Ford 3000 Tractor

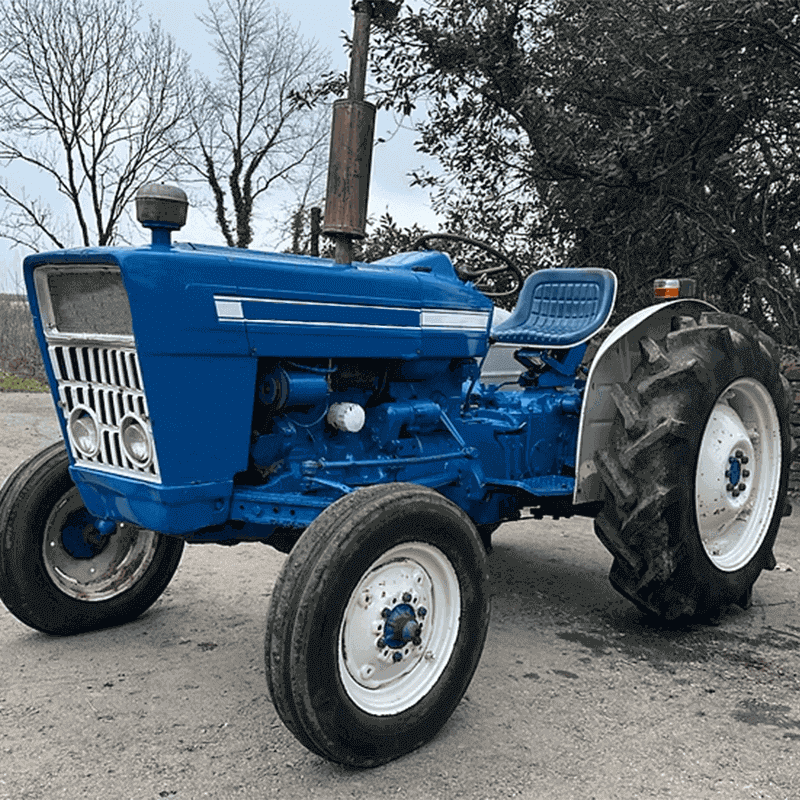

The Ford 3000 was part of Ford’s global “1000 Series,” a line of tractors that set a new standard for the brand. It was a versatile utility tractor, powerful enough for serious farm work but nimble enough for smaller tasks. Its straightforward mechanical design makes it a favorite among owners who prefer to do their own repairs.

Rugged Performance and Easy Maintenance

- The Ford 3000’s rugged engine and sturdy chassis deliver reliable performance even after decades of work.

- Its simple mechanical design reduces the risk of breakdowns and makes repairs straightforward.

- Fewer electronics mean fewer failures, keeping the tractor working when it’s needed most.

Affordable and Accessible Parts

- Replacement parts for the Ford 3000 are widely available and budget-friendly.

- This makes it practical to keep in operation, whether for daily farm work or as a restored classic.

- Owners appreciate the low maintenance costs and ease of sourcing quality components

Common Ford 3000 Tractor Problems in 2025

After 50+ years of service, these tractors exhibit common wear patterns. Here are the most frequent problems owners face today, presented in a question-and-answer format to help you diagnose your issue quickly.

Problem 1: 3-Point Hitch Lifts Weakly or Not at All

Q: “My Ford 3000’s 3-point hitch can lift a light rake, but struggles or fails with my heavy rotary cutter. What’s wrong?”

Answer: This usually means loss of hydraulic pressure under load. The system may handle light tasks, but it fails when demand increases. Common causes include:

- Worn Hydraulic Pump: Internal wear reduces pressure output, even if it moves enough fluid for light loads. A pressure test confirms this.

- Failing Piston Seal: Worn seals inside the lift cylinder allow fluid to bypass, especially under heavy load. A key sign is the hitch drifting down after shutdown.

- Clogged Suction Screen/Filter: Debris restricts fluid flow to the pump, causing slow, jerky, or weak lift.

- Leaking Relief Valve: A weak or stuck valve sends fluid back to the sump before reaching full pressure.

Troubleshooting Steps:

- Check fluid level and condition. Milky or foamy oil means water or air contamination.

- Clean the hydraulic suction screen.

- Do a leak-down test: Lift an implement, shut off the tractor, and note how quickly it drops. A fast drop means a seal or valve leak.

- If issues persist, replace the hydraulic pump to restore lifting power.

Problem 2: Engine Stalls or Won’t Start

Q: “My gas-powered Ford 3000 starts and runs for a few minutes, then sputters and dies. Now it won’t start at all. I cleaned the carburetor, but it didn’t help.”

Answer: This usually means fuel starvation or a weak ignition system that fails when hot.

For Gasoline Models:

- Clogged Fuel Filters: Check the screen in the sediment bowl and any inline filter for rust or debris.

- Faulty Fuel Pump: A weak mechanical pump can’t keep the carburetor bowl full.

- Carburetor Issues: A stuck float or hidden blockage can still cause problems, even after cleaning.

- Ignition Problems: Overheated coils produce weak sparks; worn points or condensers need regular replacement.

For Diesel Models:

- Air in Fuel Lines: Even a small leak can let in air, stalling the engine until the system is bled.

- Clogged Fuel Filters: Diesel systems are highly sensitive to blockages, starving the injection pump.

- Failing Lift Pump: Without a steady fuel supply, the injection pump can’t run.

Pro Tip: On these older tractors, start with the fuel system. Most “engine issues” are really fuel delivery problems—fix that first before moving to ignition or compression checks.

Problem 3: PTO is Difficult to Engage or Won’t Stop Spinning

Q: “I have to grind the gears to get my PTO engaged, and sometimes it keeps spinning even when I disengage it. Is this a major repair?”

Answer: This indicates a problem with the PTO clutch or its linkage. The Ford 3000 has a two-stage clutch. Pushing the pedal halfway down disengages the transmission, while pushing it all the way to the floor should disengage the PTO.

- Improper Clutch Adjustment: The most common cause is that the clutch linkage is out of adjustment. Over time, wear can change the pedal’s travel, preventing it from fully disengaging the PTO clutch disc.

- Worn PTO Clutch Disc: The clutch disc itself can be worn out, warped, or contaminated with oil, causing it to drag and not release cleanly.

- Worn Pilot Bearing: A worn pilot bearing in the flywheel can cause the input shaft to continue spinning even with the clutch disengaged, leading to grinding.

This issue often requires splitting the tractor to access the clutch assembly, which is a significant job. However, always start by attempting to adjust the clutch linkage according to the service manual.

Maintenance Tips for Ford 3000 in 2025

A consistent maintenance routine will solve most problems before they start and dramatically extend the life of your Ford 3000.

Change Fluids Religiously:

- Engine Oil: Change the oil and filter every 100 hours of operation, or at least once a year.

- Hydraulic Fluid: Change the hydraulic fluid and clean the suction screen every 300-400 hours. Use a fluid that meets the Ford M2C134-D specification. This is critical for hydraulic health.

Keep Fuel Clean: Always use clean fuel from a trusted source. Regularly check and clean the sediment bowl to remove water and debris. Replace fuel filters annually.

Grease Everything: The Ford 3000 has numerous grease points on its steering linkage, front axle pivots, and three-point hitch. Grease them every 10-20 hours of use to prevent wear.

Service the Air Filter: The oil-bath air cleaner needs regular service. Clean and refill it with fresh oil to ensure the engine breathes clean air.

Check Electrical Connections: Keep battery terminals clean and tight. Check wiring for cracks or bare spots to prevent shorts.

Recommended Ford 3000 Tractor Parts & Upgrades

When parts do wear out, using high-quality replacements is essential. For a tractor of this age, certain upgrades can also dramatically improve reliability.

| Part / Upgrade | Failure Issues | Recommended Action |

|---|---|---|

| Electronic Ignition Kit | The original points and condenser wear out, require adjustment, and are prone to moisture issues. | This is the single best reliability upgrade for a gas Ford 3000. It provides a stronger, more consistent spark and eliminates routine adjustments. |

| Hydraulic Pump | Decades of use cause internal wear, leading to a loss of pressure and lifting capacity. | When your lift is weak, a new pump is often the only permanent fix. Ensure you get a quality replacement to restore full power. |

| Complete Fuel System Kit | Rust from the tank clogs the sediment bowl, fuel lines, and filters, starving the engine of fuel. | Replace the sediment bowl assembly, fuel lines, and filters all at once to ensure a clean, reliable fuel supply from tank to carburetor/injectors. |

| Starter | Old starters can develop dead spots, have worn bushings, or weak solenoids, leading to no-start situations. | A new, high-torque starter can make a huge difference, especially on diesel models in cold weather. |

| Gauges and Sending Units | Original gauges can fail, leaving you blind to temperature, oil pressure, or fuel level. | Replace non-working gauges immediately. Operating without knowing your engine’s vitals is a major risk. |

At FridayParts, we specialize in providing high-quality, affordable aftermarket Ford tractor parts for machines like the Ford 3000. Our vast inventory ensures you can find everything from a complete ignition kit to a new hydraulic pump to keep your classic tractor in peak condition.

Summarize

The Ford 3000 tractor is a testament to engineering. Its continued presence on farms and properties in 2025 is proof of its durability. While age brings predictable challenges like weak hydraulics and tired ignition systems, these problems are well-documented and solvable. By performing regular maintenance and investing in quality replacement Ford tractor parts when needed, you can ensure your Ford 3000 will continue to be a reliable workhorse for the next generation.