If you’ve ever had to replace a gasket on your engine, you’ve probably faced the tough choice between different gasket materials. Among the most common options are graphite and Multi-Layered Steel (MLS) gaskets. But what’s the difference between Graphite vs MLS? And which one should you choose for your specific needs?

At FridayParts, we’ve helped countless customers navigate this exact decision. With our inventory of over 70,000 top-quality aftermarket parts, we know a thing or two about what works best in different situations. Let’s break down the key differences between graphite and MLS gaskets to help you make the right choice.

Graphite vs MLS: What Are They?

What Are Graphite Gaskets?

Graphite gaskets have been around for decades, and for good reason. These gaskets are made from compressed graphite material, sometimes reinforced with metal. The graphite used is often flexible graphite, which is created by treating natural graphite flakes with acids and then compressing them into sheets.

The big selling point of graphite gaskets is their excellent sealing ability. Graphite has natural properties that allow it to fill small imperfections in mating surfaces. This makes it great for older engines or applications where the surfaces might not be perfectly flat.

Graphite also handles heat incredibly well. It can withstand temperatures up to 1500°F (815°C) in some cases, which is why it’s often used in high-temperature applications like exhaust manifolds. Plus, graphite doesn’t stick to metal surfaces, making it easier to remove when it’s time for replacement.

However, graphite gaskets do have some drawbacks. They’re more prone to crushing under high clamping loads, and they don’t always recover well from compression. This means they might not be the best choice for applications with significant pressure fluctuations.

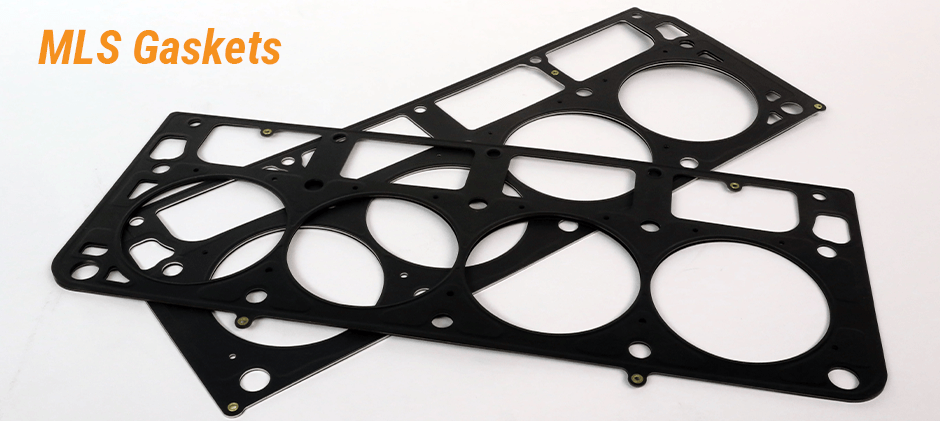

What Are MLS Gaskets?

Multi-layered steel (MLS) gaskets represent the newer technology in the gasket world. As the name suggests, these gaskets consist of multiple layers of steel, typically ranging from three to five layers. The outer layers typically feature elastomer coatings that help create a tight seal.

MLS gaskets have become the standard in modern engines, especially in high-performance and high-compression applications. The reason? They offer exceptional durability and can handle much higher cylinder pressures than traditional gasket materials.

The design of MLS gaskets allows them to both compress and spring back, enabling them to adapt to the dynamic conditions inside an engine. This is particularly valuable in engines that experience thermal cycling (repeated heating and cooling) or in high-revving engines where cylinder pressures fluctuate rapidly.

One of the biggest advantages of MLS gaskets is their ability to maintain a seal over time. Unlike some other gasket materials that can deteriorate with age, MLS gaskets tend to remain effective for the long haul, which is why most modern manufacturers use them as original equipment.

Durability Comparison: Graphite vs MLS

When it comes to longevity, MLS gaskets generally take the crown. Their multi-layer steel construction gives them excellent resistance to the constant pressure cycles and temperature changes that engines go through. This makes MLS gaskets less likely to blow out or fail prematurely, even in high-stress environments.

Graphite gaskets, while durable in their own right, typically don’t match the longevity of MLS gaskets in modern engines. They’re more susceptible to compression set (permanent deformation) over time, which can lead to leaks as the engine ages. This is particularly true in applications with high cylinder pressures or significant vibration.

However, it’s worth noting that in certain specific applications, graphite gaskets might actually outlast MLS. For example, in extremely high-temperature environments where thermal cycling is limited, the heat resistance of graphite can give it an edge in durability.

At FridayParts, we’ve seen both types of gaskets perform well when properly matched to the application. The key is choosing the right gasket for your specific engine and operating conditions, which is something our team can help you with.

Temperature Resistance: Graphite vs MLS

Temperature resistance is a critical factor in gasket selection, and both graphite and MLS have different characteristics in this area.

Graphite gaskets are legendary for their heat resistance. Pure flexible graphite can handle temperatures well over 1000°F without breaking down. This makes graphite an excellent choice for exhaust components, where temperatures can soar. Graphite also maintains its sealing properties across a wide temperature range, which means it doesn’t harden or become brittle with heat exposure.

MLS gaskets also offer good temperature resistance, but through a different mechanism. The steel layers in MLS gaskets can handle high temperatures, while the elastomer coatings are typically designed to withstand the normal operating temperatures of modern engines. However, in extreme heat applications, some elastomer coatings may begin to deteriorate.

What our customers tell us: “I replaced my blown head gasket with an MLS gasket from FridayParts three years ago, and it’s still running strong, even though I occasionally push my engine hard on weekend trips.” – Customer from Texas

The temperature advantage really depends on the specific application. For most modern automotive engines, MLS gaskets provide more than enough heat resistance. But for specialized high-heat applications like turbochargers or exhaust systems, graphite might be the better option.

Graphite vs MLS Cost Effectiveness: Price vs Performance

When it comes to your wallet, there’s usually a noticeable difference between graphite and MLS gaskets, but the true cost goes beyond just the initial purchase price.

Graphite gaskets typically cost less upfront than their MLS counterparts. This makes them attractive for budget-conscious repairs or for older vehicles where investing in premium components may not be economically sensible. The lower cost of graphite gaskets also makes them popular for applications where gaskets need to be replaced more frequently as part of regular maintenance.

MLS gaskets, on the other hand, generally come with a higher price tag. The complex manufacturing process involving multiple steel layers and precision coatings drives up the cost. However, the increased durability of MLS gaskets often means fewer replacements over the life of the engine, which can make them more cost-effective in the long run.

At FridayParts, we offer both options at competitive prices, allowing you to make the choice that best fits your budget and needs. Our team can help you weigh the initial cost against long-term performance to find the most cost-effective solution for your specific situation.

Application Suitability: Choosing the Right Gasket

Selecting between graphite and MLS gaskets ultimately comes down to matching the material to your specific application. Here’s a quick guide to help you decide:

Graphite gaskets tend to excel in:

- Older engines with less-than-perfect mating surfaces

- High-temperature applications like exhaust manifolds

- Static seals where there’s minimal movement or vibration

- Applications where conformability to irregular surfaces is essential

- Low-pressure systems where the crush resistance isn’t as critical

MLS gaskets are typically better for:

- Modern high-compression engines

- Applications with significant thermal cycling

- High-performance or turbocharged engines

- Engines that experience a lot of vibration or movement

- Situations where long-term reliability is paramount

Remember that engine design has evolved over the years, and newer engines are often designed specifically with MLS gaskets in mind. If you’re working with a modern engine, switching from MLS to graphite might require additional considerations to ensure proper sealing.

At FridayParts, we stock a wide range of both graphite and MLS gaskets for various applications, from generators to excavators, loaders, tractors, and more. Our extensive inventory ensures you’ll find the right gasket for your specific equipment.

Installation Considerations: Graphite vs MLS

The installation process differs somewhat between graphite and MLS gaskets, and these differences can significantly impact performance.

Graphite gaskets are generally more forgiving during installation. They conform more easily to surface irregularities and typically don’t require as perfect a surface finish as MLS gaskets. This can make graphite a better choice for DIY repairs or situations where precision surface preparation equipment isn’t available.

However, graphite gaskets do require careful handling during installation. The material can be more fragile than steel, and tearing or damaging the gasket during installation can lead to immediate failure. Additionally, proper torquing is critical with graphite gaskets to prevent over-compression.

MLS gaskets demand more precise installation. The mating surfaces must be very clean and have the correct surface finish (typically smoother than what’s required for graphite). MLS gaskets also usually require specific torque sequences and values, which must be followed exactly. On the plus side, MLS gaskets are typically more robust during the installation process and less prone to damage from handling.

Regardless of which type you choose, following the manufacturer’s installation instructions is crucial for success. At FridayParts, we can provide guidance on proper installation techniques for the gaskets we sell, helping to ensure your repair goes smoothly.

FAQs About Graphite vs MLS

Are MLS head gaskets better than graphite?

MLS head gaskets are generally better for modern engines with high compression ratios and thermal cycling. They offer superior durability and recovery from compression. However, graphite gaskets might be better for specific applications like extremely high temperatures or where surface imperfections exist.

How long do MLS gaskets last compared to graphite?

MLS gaskets typically last longer than graphite gaskets in most applications, often matching the lifespan of the engine itself when properly installed. Graphite gaskets may need replacement more frequently, especially in high-stress applications, though actual lifespan varies based on operating conditions.

Can I replace an MLS gasket with a graphite one?

While technically possible in some cases, replacing an MLS gasket with a graphite one isn’t generally recommended for modern engines. These engines are designed with MLS gaskets in mind, including specific surface finishes and bolt torque specifications. Making this switch might lead to sealing issues or premature failure.

Why are MLS gaskets more expensive than graphite?

MLS gaskets cost more due to their complex manufacturing process involving multiple precision-made steel layers and specialized coatings. The materials and technology required to produce high-quality MLS gaskets drive up the price, though their longer lifespan often makes them more cost-effective in the long run.

Which gasket type is best for high-performance engines?

For most high-performance engines, especially those with forced induction (turbochargers or superchargers), MLS gaskets are the preferred choice. They handle the increased cylinder pressures, higher temperatures, and more extreme thermal cycling that high-performance engines experience better than graphite gaskets typically can.

At FridayParts, we’re committed to helping you find the right parts for your needs. Whatever gasket you are looking for, or any other replacement parts for your off-road machinery, our team is here to help. With over 70,000 top-notch OEM-quality aftermarket parts and warehouses across the globe, we can get you the parts you need quickly and at a fair price.

Reach out to our support team at +1 833-308-1855 or info@fridayparts.com, Monday to Friday from 9 am-6 pm EST, and we’ll help you get back on the move in no time.