If you’ve ever wondered why your diesel engine doesn’t overheat even under heavy loads, you might want to thank the humble oil cooler. These devices play a critical role in keeping your engine running smoothly, yet many equipment owners overlook their importance. At FridayParts, we’ve helped thousands of customers solve their cooling system problems, and we’re here to share that knowledge with you.

What Are Diesel Oil Coolers and Why Do They Matter?

Diesel oil coolers are heat exchangers designed to lower the temperature of engine oil as it circulates through your diesel engine. Think of them as tiny radiators specifically for your oil. As oil flows through the cooler, heat transfers from the hot oil to the cooling medium (usually air or coolant), bringing the oil temperature down before it returns to the engine.

Why does this matter? Hot oil is thin oil, and thin oil doesn’t protect your engine components as well. When your diesel engine works hard—pulling heavy loads, climbing steep grades, or running for extended periods—oil temperatures can skyrocket. Without a proper oil cooler, this can lead to faster oil breakdown, increased engine wear, and eventually, costly repairs.

In modern diesel engines, where tolerances are tighter and performance expectations higher, oil coolers aren’t just nice-to-have accessories—they’re essential components for engine longevity. That’s why at FridayParts, we stock a wide range of high-quality aftermarket oil coolers for various diesel applications, from generators to excavators and everything in between.

Types of Diesel Oil Coolers You Should Know

Not all oil coolers are created equal. Depending on your equipment and operating conditions, you’ll need to choose the right type for optimal performance. Here are the main types you’ll encounter:

Air-Cooled Oil Coolers

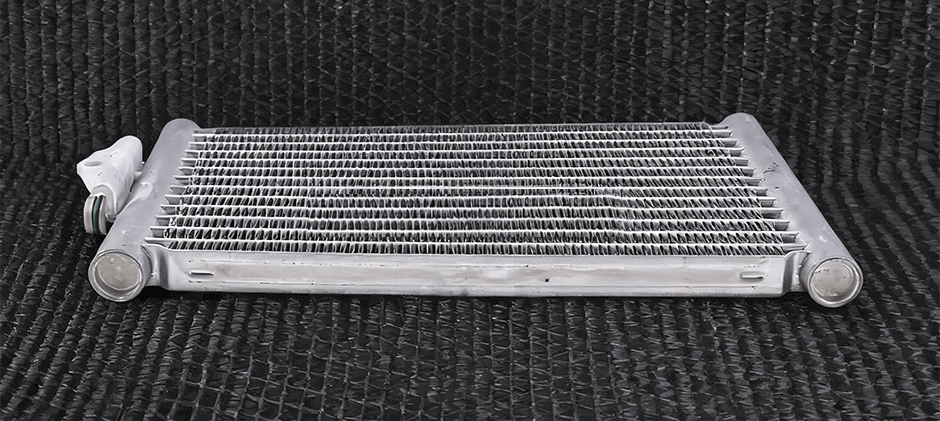

Air-cooled oil coolers use ambient air to remove heat from the oil. They typically consist of a series of metal tubes with fins attached. As oil flows through the tubes, air passes over the fins, carrying away heat. These coolers are most common in applications where space is at a premium or where there’s plenty of airflow available.

The advantages of air-cooled systems include simpler installation (no need to integrate with the engine’s coolant system) and fewer potential points of failure. However, their cooling capacity is directly tied to airflow and ambient temperature, which means they might struggle in extremely hot environments or when airflow is restricted.

Many smaller diesel generators and some construction equipment use air-cooled oil coolers because of their simplicity and reliability. If you’re operating in moderate climates with good ventilation, an air-cooled system might be all you need.

Liquid-Cooled Oil Coolers

Liquid-cooled (or water-cooled) oil coolers use the engine’s coolant system to remove heat from the oil. These typically come in two forms: plate-and-fin designs or tube-and-shell configurations. In both cases, hot oil and cool engine coolant pass near each other without mixing, allowing heat to transfer from the oil to the coolant.

The main advantage of liquid-cooled systems is their superior cooling capacity. Since engine coolant can remove heat more efficiently than air, these systems can handle higher heat loads, making them ideal for heavy-duty applications or extreme operating conditions.

Most larger diesel engines, including those in trucks, large generators, and heavy construction equipment, use liquid-cooled oil coolers. If your equipment regularly operates under heavy loads or in hot environments, a liquid-cooled system is probably your best bet.

How Diesel Oil Coolers Boost Engine Performance

The benefits of a properly functioning oil cooler go beyond just preventing overheating. Here’s how these components contribute to overall engine performance:

Extended Oil Life

Heat is the enemy of engine oil. Every 20°F increase in oil temperature can cut oil life in half. By keeping oil temperatures in check, coolers help extend oil change intervals and reduce maintenance costs. We’ve seen customers at FridayParts save hundreds on oil changes simply by upgrading to a more efficient oil cooler.

Improved Lubrication

Oil viscosity—its thickness or flowability—changes with temperature. When oil gets too hot, it thins out and doesn’t provide adequate lubrication. This can lead to metal-on-metal contact between engine components, accelerating wear. Coolers help maintain optimal oil viscosity, ensuring proper lubrication even under demanding conditions.

Reduced Engine Wear

By maintaining proper oil temperature and viscosity, oil coolers help protect critical engine components from excessive wear. This is especially important in high-stress areas like bearings, cylinder walls, and valve trains. Many of our customers report significantly extended engine life after upgrading their cooling systems, with some heavy-duty engines lasting 25-30% longer before requiring major overhauls.

Better Fuel Efficiency

Believe it or not, proper oil temperature can impact fuel efficiency. When oil is too hot or too cold, internal engine friction increases, requiring more fuel to produce the same power output. By keeping oil at optimal temperatures, coolers help your diesel engine operate at peak efficiency.

Selecting the Right Oil Cooler for Your Diesel Engine

Choosing the right oil cooler isn’t just about buying the biggest or most expensive option. You need to match the cooler to your specific needs. Here’s what to consider:

Heat Dissipation Requirements

Start by understanding how much heat your engine generates under typical operating conditions. Larger engines or those that regularly work under heavy loads will need coolers with greater heat dissipation capacity. Check your engine manufacturer’s specifications for recommended cooling system requirements.

If you’re upgrading from a stock cooler, consider your operating conditions. Do you regularly tow heavy loads? Work in extremely hot environments? Run your equipment for extended periods? All these factors increase heat load and might justify a larger cooler.

Space and Mounting Considerations

Oil coolers come in various shapes and sizes, and you’ll need to ensure the one you choose fits in your available space. Consider not just the dimensions of the cooler itself, but also allowances for oil lines, mounting brackets, and adequate airflow (for air-cooled systems).

At FridayParts, we can help you find coolers that match your space constraints while still meeting your cooling needs. Our extensive catalog includes options for even the most challenging installations.

Compatibility with Existing Systems

Make sure the cooler you select is compatible with your engine’s oil pressure, flow rates, and existing fittings. Mismatched components can lead to poor performance or even system failures. Pay particular attention to port sizes and thread types to ensure a proper fit.

For liquid-cooled systems, you’ll also need to verify compatibility with your engine’s coolant system. This includes temperature ratings, pressure capabilities, and chemical compatibility with your coolant type.

Installation Tips for Maximum Cooling Efficiency

Even the best oil cooler won’t perform properly if installed incorrectly. Here are some tips to ensure you get maximum cooling efficiency:

Proper Mounting Location

For air-cooled systems, location is critical. Mount the cooler where it will receive good airflow, ideally in front of or beside radiators or fans. Avoid locations where the cooler might be blocked by other components or where it might be subjected to direct debris impact.

For liquid-cooled systems, ensure the cooler is securely mounted and that coolant lines are routed to avoid kinks or potential chafing points. Keep in mind that liquid-cooled systems should be installed to allow for easy bleeding of air from the system.

Correct Plumbing Practices

Use appropriately sized oil lines that won’t restrict flow. In general, larger diameter lines are better for reducing restriction, but follow your cooler manufacturer’s recommendations. Ensure all connections are tight and use appropriate fittings—typically AN fittings or industry-standard adapters.

When routing oil lines, avoid sharp bends and potential pinch points. Remember that oil lines will carry hot oil under pressure, so route them away from exhaust components and moving parts to prevent damage.

Thermostat Considerations

Many advanced oil cooling systems include thermostatic controls that only route oil through the cooler when it reaches a certain temperature. This helps prevent overcooling during cold starts. If your system includes a thermostat, ensure it’s installed according to the manufacturer’s directions and that it opens at the correct temperature.

Maintenance Tips to Extend Oil Cooler Life

Like any engine component, oil coolers require regular maintenance to function properly. Here’s how to keep yours in top shape:

Regular Inspection and Cleaning

Periodically check your oil cooler for signs of damage, leaks, or blockages. For air-cooled systems, inspect fins for bent or crushed sections that might restrict airflow. Use compressed air or a soft brush to clear debris from between fins, but be careful not to damage them.

For liquid-cooled systems, check for any signs of coolant or oil leakage around gaskets or fittings. Also, verify that coolant levels remain stable, as a drop might indicate a leak in the oil cooler.

Flushing and Flow Testing

Over time, oil coolers can develop internal blockages from sludge or debris. If you suspect restricted flow, consider having your cooler professionally flushed or flow-tested. Most shops that service radiators can also service oil coolers.

If your engine has experienced a failure that created metal particles (like a spun bearing), your oil cooler should be thoroughly flushed or replaced, as it can harbor debris that could damage your rebuilt or replacement engine.

When to Replace vs. Repair

Minor leaks in some oil coolers can be repaired, particularly in older, serviceable designs. However, many modern coolers are sealed units that must be replaced if damaged. As a general rule, if your cooler shows signs of external damage, significant corrosion, or internal blockage that can’t be cleared with flushing, replacement is usually the safer option.

At FridayParts, we stock a wide range of replacement oil coolers for virtually any diesel application. Our OEM-quality aftermarket parts offer the reliability you need at prices that won’t break the bank.

Troubleshooting Common Oil Cooler Problems

Even with proper maintenance, oil coolers can sometimes develop issues. Here’s how to diagnose and address common problems:

Overheating Despite a Functioning Cooler

If your engine oil is overheating despite having an oil cooler installed, several factors could be at play. First, check that the cooler is receiving adequate airflow (for air-cooled systems) or coolant flow (for liquid-cooled systems). Restricted flow on either the oil or cooling side can dramatically reduce efficiency.

Next, verify that the cooler is properly sized for your application. An undersized cooler simply may not be able to dissipate the heat your engine generates, especially if operating conditions have changed (like adding more power or increasing load).

Finally, consider that the problem might not be with the cooler at all. Low oil levels, a malfunctioning oil pump, or internal engine problems can all cause oil temperature issues that even a perfect cooler can’t fix.

Detecting and Addressing Leaks

Oil leaks from coolers typically occur at connection points or from cracks in the cooler body. For connection leaks, try tightening fittings (but don’t overtighten, which can cause more damage). If that doesn’t work, check for damaged threads, missing or damaged O-rings, or the wrong type of fittings.

For cracks or internal leaks in liquid-cooled systems, you might notice oil in your coolant (it will typically appear as floating globules) or coolant in your oil (giving it a milky appearance). Either condition requires immediate attention, as mixing of these fluids can cause serious engine damage.

When to Seek Professional Help

While many oil cooler issues can be addressed by a knowledgeable equipment owner, some situations call for professional assistance. If you’re experiencing internal leaks between oil and coolant systems, have metal debris in your oil system from an engine failure, or can’t identify the source of an overheating problem, it’s best to consult with a qualified technician.

At FridayParts, our support team can help guide you through basic troubleshooting and help you determine when it’s time to bring in a professional. Our goal is to get your equipment back up and running as quickly and cost-effectively as possible.

The FridayParts Advantage for Your Diesel Oil Cooler Needs

When it comes to finding the right oil cooler for your diesel equipment, FridayParts offers advantages you won’t find elsewhere. Just like we helped Joseph in Cameroon find that elusive generator part back in 2008, we’re ready to help you find exactly what you need for your cooling system.

With over 70,000 top-notch OEM-quality aftermarket parts online and warehouses across the United States, Canada, Germany, and China, we can get you the right part fast. Our commitment to quality replacements, fair prices, and lightning-fast deliveries means you can get back to work quickly without breaking the bank.

Whether you’re maintaining a single generator or managing a fleet of heavy equipment, we’ve got you covered. Our team has the expertise to help you select the right oil cooler for your specific application, ensuring optimal performance and longevity for your diesel engines.

FAQ: Diesel Oil Coolers

What happens if my diesel engine doesn’t have an oil cooler?

Without an oil cooler, your diesel engine oil can reach dangerously high temperatures, especially under heavy loads. This leads to faster oil breakdown, reduced lubrication properties, and accelerated engine wear. In extreme cases, it can contribute to engine seizure or failure. For most modern diesel engines, an oil cooler isn’t optional—it’s essential for reliable operation and longevity.

How do I know if my diesel oil cooler is failing?

Common signs of oil cooler failure include rising engine oil temperatures, oil leaks, coolant in your oil (milky appearance), oil in your coolant, or engine overheating despite normal coolant temperatures. If you notice any of these symptoms, it’s important to address them quickly before more serious engine damage occurs.

Can I upgrade my stock diesel oil cooler for better performance?

Absolutely! Many stock oil coolers are designed for moderate use. If you regularly operate your equipment under heavy loads, in hot environments, or have modified your engine for more power, upgrading to a larger or more efficient oil cooler can provide significant benefits. Just ensure any upgrade is compatible with your engine’s oil system and has proper mounting locations.

How often should I replace my diesel oil cooler?

Unlike wear items such as filters or belts, oil coolers don’t have a set replacement interval. With proper maintenance, a quality oil cooler can last the life of the engine. However, you should consider replacement if you notice leaks, damage, or reduced cooling efficiency that can’t be resolved through cleaning or minor repairs.

Will a bigger oil cooler always provide better cooling?

Not necessarily. While a larger cooler generally has more cooling capacity, other factors like airflow, oil flow rates, and installation location play crucial roles in actual performance. An oversized cooler with poor airflow might actually perform worse than a properly sized and placed smaller unit. It’s important to select a cooler that’s appropriately sized for your specific engine and operating conditions.