In the world of off-road machinery, unexpected breakdowns can cost both time and productivity. Heavy equipment like excavators, loaders, tractors, and trucks depends on precise diagnostics to stay operational. That’s where DTC fault codes (Diagnostic Trouble Codes) come in — your key to understanding what’s happening under the hood before small issues turn into costly repairs.

In this guide, we’ll walk you through how to decode DTC fault codes, how they work across different systems (including J1939 for heavy-duty equipment), and how to apply this knowledge to keep your machinery performing at its best.

Key Takeaways

- DTC fault codes provide insight into mechanical or electrical problems in off-road machinery.

- Understanding code structure helps locate issues faster.

- J1939-based machinery uses SPN and FMI identifiers instead of alphanumeric OBD-II codes.

- Using reliable parts ensures that repairs are long-lasting and cost-effective.

What Are DTC Codes?

DTC codes are the digital “language” used by an equipment’s electronic control system to flag mechanical or electrical problems. When a piece of off-road machinery detects an abnormal condition — a faulty sensor, poor air-fuel ratio, low pressure, or communication issue — its control module logs a code that identifies the problem area.

For example, just as a “check engine” light alerts a car driver, a DTC code provides specific fault data for heavy equipment operators and service technicians.

These codes are essential for:

- Reducing downtime by identifying issues early

- Improving maintenance planning

- Extending component life through preventive action

Pro Tip: For durable repair solutions and performance upgrades, explore high-quality truck parts and components that match your machinery’s specific model — from engines to wiring sensors.

Types of DTC Codes

DTCs can be divided into two main categories — each defining how urgently a repair is needed:

| Aspect | Critical DTC Codes | Non-Critical DTC Codes |

|---|---|---|

| Meaning | Problems that could cause immediate system failure or safety issues | Minor or emission-related issues not requiring instant intervention |

| Examples | Low oil pressure, coolant overheat, and engine knock were detected | Oxygen sensor malfunction, emissions leak |

| Response Time | Immediate action required | Schedule a repair soon |

| Recommended Action | Stop equipment operation, perform diagnostics | Plan maintenance, monitor symptoms |

Detecting and categorizing codes correctly ensures machinery remains safe, compliant, and ready for every job site.

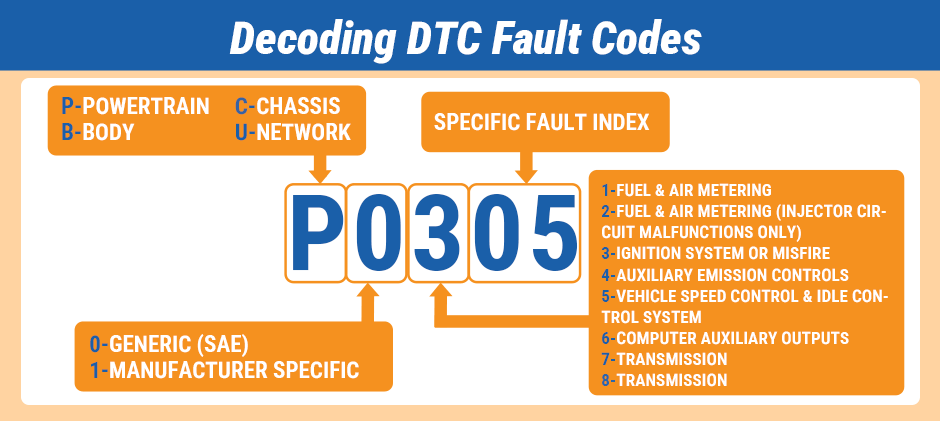

Decoding the Structure of a DTC Code

A DTC code typically follows a five-character structure. Each character reveals information about where the fault is detected and the type of issue.

Example: P0305

1. First Character (System Letter)

- P: Powertrain (engine, fuel, or transmission)

- B: Body (cabin elements like HVAC or safety sensors)

- C: Chassis (braking, suspension, steering systems)

- U: Communication (network or control module faults)

2. Second Character (Code Type)

- 0: Generic/SAE standardized code

- 1: Manufacturer-specific fault code

3. Third Character (Subsystem Area)

- 1: Fuel & air metering system

- 2: Injector circuit malfunction

- 3: Ignition or misfire detection

- 4: Emission control systems

- 5: Vehicle speed or idle control

- 6: Computer or output circuit

- 7–8: Transmission-related

4. Last Two Characters (Fault Detail)

These numeric digits identify the specific fault. For example:

- P0301: Cylinder 1 misfire detected

- P0420: Catalyst system efficiency below threshold

As shown in decoding charts, each digit plays a role like a postal code — directing technicians to the exact area of failure.

Common DTC Codes in Heavy Equipment

Below is a list of frequently encountered codes across off-road engines, construction trucks, and agricultural machinery:

| Code | Fault Description |

|---|---|

| P0101 | Mass Air Flow (MAF) sensor circuit range/performance issue |

| P0110 | Intake air temperature sensor malfunction |

| P0300 | Random/multiple cylinder misfire detected |

| P0442 | Small leak in the evaporative emission system |

| P0500 | Vehicle speed sensor malfunction |

| P0706 | Transmission range sensor circuit fault |

| P0606 | ECU internal fault, processing error |

These are common across many engine platforms used in excavators, loaders, and articulated trucks. Regular code monitoring helps ensure fuel efficiency and emission compliance.

List of Permanent DTC Codes

Permanent DTCs differ from temporary ones. They remain stored even after repairs until the machine passes specific self-tests over several operating cycles.

| Category | DTC Code | Description |

|---|---|---|

| Powertrain | P0300 | Random misfire across multiple cylinders |

| Powertrain | P0420 | Catalyst efficiency below standard |

| Powertrain | P0171 | System too lean (Bank 1) |

| Powertrain | P0442 | Small EVAP leak detected |

| Chassis | C0561 | ABS is disabled due to an internal condition |

| Body | B0020 | Airbag deployment loop fault |

| Network | U0100 | Lost communication with ECM |

| Network | U0121 | Lost communication with ABS |

Permanent codes help confirm whether repairs were successful or if further validation is required before resetting the ECM

How to Interpret a J1939 DTC Code?

Most off-road and heavy-duty machines (such as excavators, graders, and articulated dump trucks) use the SAE J1939 system, not the standard OBD-II structure. Understanding J1939 fault messages ensures you can interpret data directly from your diagnostic tool.

Each J1939 DTC includes specific identifiers:

- SPN (Suspect Parameter Number): Identifies the affected sensor or circuit

- FMI (Failure Mode Identifier): Explains the type of failure — e.g., open circuit (FMI 5) or high voltage (FMI 3)

- OC (Occurrence Count): Number of times the fault occurred

- SA (Source Address): The module reporting the issue (e.g., Engine Control Module or Transmission Controller)

Example:

SPN 102 FMI 3 → Intake manifold pressure sensor has high voltage.

Using a diagnostic reader, you can cross-reference these values with your equipment service manual to pinpoint the defective component precisely.

How to Read a DTC Code from Your Machine?

Here’s a quick step-by-step to retrieve codes correctly:

- Locate the Diagnostic Port – Usually near the operator’s seat or control console in heavy machinery.

- Connect the Diagnostic Tool – Plug in your DTC scanner or data monitor.

- Power Up and Scan – Turn on the ignition; retrieve active and stored codes.

- Record and Compare – Note down fault codes and refer to the service chart or online reference.

- Repair and Recheck – Replace or repair defective parts, clear codes, then verify operation.

Tip: If the same fault reappears after repair, inspect connectors, harnesses, or ECU calibration rather than replacing components repeatedly.

Conclusion

Decoding DTC fault codes is not just about reading numbers — it’s about understanding the heartbeat of your equipment. Proper interpretation protects engines, reduces unplanned downtime, and ensures safe operation on tough jobsites.

At FridayParts, we make every repair easier with a vast availability of OEM-quality and aftermarket replacement parts at competitive prices. From sensors and valves to complete control systems, our truck parts collection covers the needs of excavators, tractors, and heavy-duty trucks of multiple brands — all tested for reliability and performance.