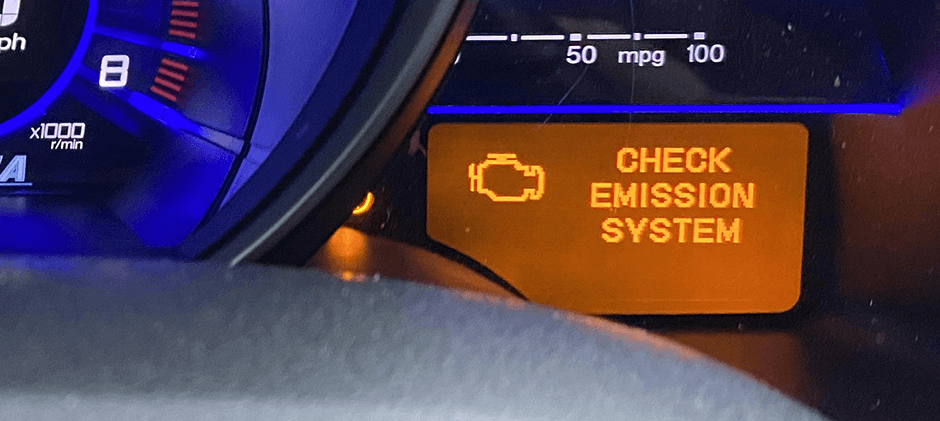

Modern off‑road machinery and heavy‑duty trucks rely on complex emission control systems to meet environmental standards and keep engines operating efficiently. When the “Check Emission System” or an equivalent warning light appears on your display, it signals that a key component—such as the EGR valve, DPF, or NOx sensor—may not be functioning properly. This article explains what that warning really means, why it happens, and how to diagnose and fix it using cost‑effective emission system parts designed for heavy equipment.

Key Takeaways

- The check emission system light warns of a fault in your machine’s exhaust after‑treatment or emission control system.

- Common culprits include clogged DPF filters, failed EGR valves, defective sensors, or faults in SCR/DEF dosing modules.

- Ignoring the warning can lead to power derate, reduced fuel efficiency, or regulatory non‑compliance.

- Systematic diagnosis, using scan tools and physical inspection, prevents unnecessary downtime and expensive repairs.

- Quality aftermarket emission system parts keep off‑road engines compliant, reliable, and economical.

What Does “Check Emission System Mean?”

When the onboard diagnostic system detects irregular exhaust gas values or component failure inside the emission control chain, it activates the warning.

In off‑road diesel engines and heavy trucks, emission control is achieved through several components working together:

| Component | Function | Common Faults |

|---|---|---|

| EGR Valve | Re‑circulates part of the exhaust gas back to the intake to reduce NOx | Carbon blockage, stuck valve |

| DPF (Diesel Particulate Filter) | Captures soot particles | Clogging due to failed regeneration |

| SCR/DEF System | Injects urea to convert NOx into harmless nitrogen | Crystallized DEF, failed injector |

| NOx Sensor | Measures nitrogen oxide downstream of the SCR | Sensor aging, contamination |

| Turbocharger | Maintains correct airflow & boosts combustion | Overheating, oil supply issues |

| Oxygen / Exhaust Temp Sensors | Feed data to the ECM to regulate combustion | Wiring corrosion, incorrect readings |

When the ECM registers data outside the expected range—such as excessive smoke, rising exhaust temperature, or incorrect sensor voltage—it activates the warning light. In many Tier 4 Final and Stage V compliant engines, this initiates power‑limiting protection to reduce emissions instantly.

Why Is My Check Emission System Light On?

Several conditions can trigger the warning:

- Incomplete DPF Regeneration – Interrupted auto‑regen cycles cause soot to accumulate until the sensor detects excess back pressure.

- Defective NOx Sensor – Fails to provide accurate feedback for urea dosing, leading to improper NOx reduction.

- Faulty EGR Valve – A stuck EGR may let too much exhaust into the intake or none at all, upsetting combustion balance.

- Low‑Quality DEF Fluid – Contaminated or crystallized fluid can damage injectors and SCR catalysts.

- Loose Connections or Corrosion – Wiring issues along the exhaust pipeline interfere with sensor readings.

- Software or Calibration Errors – ECU firmware mismatches or incomplete updates can misread sensor data.

Causes of the “Check Emission System” Warning Light

While every machine model behaves slightly differently, the core causes can be categorized into three technical groups:

1. Mechanical Failures

- Damaged turbocharger impeller causing oil leakage into the exhaust

- Cracked exhaust manifold altering back‑pressure ratios

- Leaking gaskets or loose clamps, introducing air into the exhaust stream

2. Sensor and Electrical Failures

- Short‑circuited heater circuits in O2 or NOx sensors

- Open or grounded wires in the DEF pump harness

- ECM voltage imbalance due to poor grounding

3. Operational and Maintenance Issues

- Extended low‑load operation without regeneration

- Using non‑spec oils that produce excess ash

- Running low‑grade diesel with high sulfur content

Signs of Emission System Faults

Even before the dashboard warning, your machine may give physical clues:

- Reduced Power or Derate – ECU limits torque to protect emission hardware.

- Increased Fuel Consumption – Faulty EGR or sensor mismanagement causes rich combustion.

- Excessive Exhaust Smoke – White (DEF issue) or black (insufficient air) smoke points to after‑treatment troubles.

- Unusual Odors or Heat – Sulfuric smell or hot exhaust manifold indicates catalytic blockage.

- Regeneration Alerts – Frequent manual regen requests hint at DPF clogging or sensor drift.

Common Causes of Emissions System Problems

Heavy machinery operates under tougher environments—dust, load cycles, and longer hours—so root causes often relate to usage patterns rather than design flaws.

- Clogged DPF Filters – The most frequent trigger. Soot buildup restricts flow and elevates exhaust temperature.

- EGR Valve Sticking – Dust, soot, or oil residue prevents proper recirculation.

- Failed Turbocharger Bearings – Oil leaks fry the DOC (Diesel Oxidation Catalyst) and sensors downstream.

- DEF System Freeze or Contamination – Poor‑quality or aged DEF creates crystals blocking lines.

- Faulty NOx or O2 Sensors – Provide incorrect data to the ECM, disturbing the emission balance.

- Cracked Exhaust Manifold – Alters pressure and temperature balance, throwing error codes.

- Damaged Wiring Harness – Vibrations or moisture intrusion cause intermittent faults.

How to Diagnose Emission System Faults?

Diagnosis in off‑road equipment differs from passenger vehicles—it relies on SAE J1939 or ISO 14229 protocols and machine‑specific diagnostic tools.

Here’s a structured approach any workshop or experienced operator can follow:

1. Retrieve Diagnostic Codes

Use a scan tool compatible with your engine manufacturer. Record SPN/FMI codes for reference.

- Example: SPN 3251 FMI 0 → DPF differential pressure high.

2. Perform Visual & Physical Checks

Inspect exhaust tubing, clamps, and gaskets for leaks or damage. Check DEF tank and filters for contamination or ice crystals.

3. Sensor Voltage Verification

Use a multimeter to check consistent voltage swings in NOx and O2 sensors. A static reading suggests sensor failure or a broken harness.

4. Backpressure and Temperature Tests

Compare the inlet/outlet temperature of the DPF using thermocouples. High delta (> 100 °C) means severe clogging.

5. Forced Regeneration or Reset

If soot accumulation crosses the threshold, perform a manual or stationary regeneration under supervision. Always ensure the machine is in a safe, ventilated area.

6. Software Recalibration

Sometimes the ECU requires a parameter reset after component replacement to clear codes permanently.

How to Fix Emissions System Faults?

Once the fault is confirmed, solutions depend on severity and available parts.

Step‑by‑Step Fix Approaches

1. Clean or Replace the DPF

- Attempt an off‑vehicle cleaning with high‑temperature baking or pneumatic soot removal.

- If the ceramic core is melted or cracked, replace the unit.

2. Replace a Failing EGR Valve

- Carbon‑filled or seized EGR valves disrupt exhaust recirculation. Install a new one, such as the EGR Valve RE537143 DZ109968 for John Deere Engine available at FridayParts.

3. Service the SCR/DEF System

- Flush lines and replace filters. If the DEF dosing module fails electrically, replacement is required.

4. Repair Wiring and Sensors

- NOx or O2 sensors like 5WK97210 for Isuzu 4HK1 Engines are plug‑and‑play replacements that restore proper feedback.

5. Check Turbo and Exhaust Seals

- Replace cracked exhaust manifolds or gaskets (for example, 1G700‑12310 Manifold for Kubota Engines).

6. Update ECM Software

After swapping emission components, force the ECU to relearn baseline parameters.

- You can find high‑quality emission system parts—including EGR valves, mufflers, manifolds, and turbochargers—compatible with John Deere, Kubota, Yanmar, Isuzu, and Caterpillar engines. FridayParts offers affordable replacements engineered for heavy‑duty diesel performance.

FAQs

1. Is it safe to operate heavy equipment with the “Check Emission System” light on?

You can continue operating temporarily, but the machine may enter a derate mode soon. Prolonged use risks overheating and component damage.

2. What’s the cost range to fix emission system issues in off‑road machinery?

Minor repairs (like replacing a sensor or gasket) may cost under $150, while DPF or SCR module replacements can exceed $1,000 in parts. But you could consider the aftermarket, where it’s usually half the price.

3. How often should I clean or replace emission parts?

DPF cleaning every 3,000 – 4,000 hours and periodic DEF filter changes every 1,000 hours help maintain system health.

4. What’s the difference between “Service After‑Treatment System” and “Check Emission System”?

Both relate to emission faults; the former often appears during or after failed DPF regeneration, while the latter indicates any emission‑related fault, including EGR or NOx sensor issues.

5. How can I prevent future issues?

- Use quality diesel fuel and DEF fluid.

- Avoid long idling.

- Perform scheduled regeneration cycles fully.

- Replace worn sensors with reliable aftermarket parts.

Conclusion

The check emission system light isn’t just a dash annoyance—it’s your equipment’s early warning against expensive repairs and compliance failures. Explore premium and affordable emission system parts—from EGR valves to NOx sensors and muffler assemblies—at FridayParts. With proper diagnosis, timely service, and trusted components from FridayParts, you can restore emission control performance and maintain productivity on any job site.