When your diesel engine starts losing power, running rough, or making unusual ticking noises, the camshaft might be trying to tell you something. At FridayParts, we’ve seen countless camshafts come through our doors over the past 16 years – some with minor wear, others looking like someone took a grinder to the lobes. Understanding what causes cam lobe wear can save you from catastrophic engine failure and help you make smart maintenance decisions. Let’s dig into what goes wrong with camshafts and, more importantly, how you can prevent it from happening to your engine.

Camshaft Function and Design

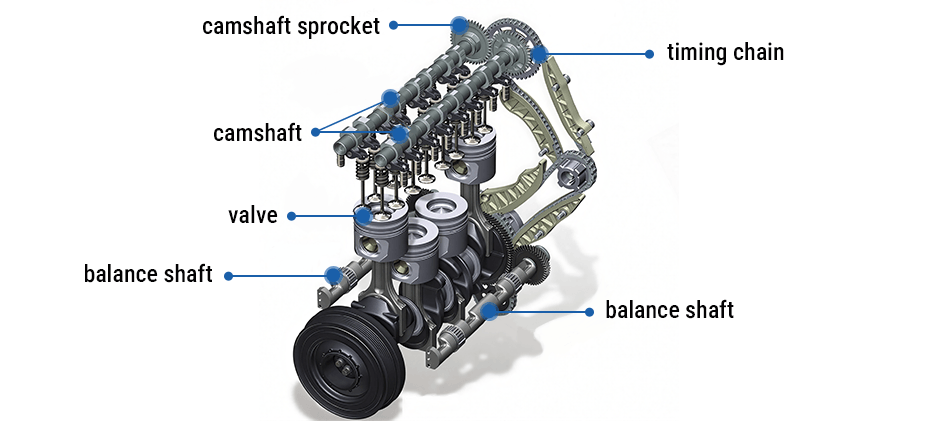

Your camshaft is the conductor of your engine’s orchestra, controlling when valves open and close with split-second precision. This long shaft with egg-shaped lobes might look simple, but it’s one of the most precisely engineered parts in your engine. Each lobe is ground to exact specifications, and even a few thousandths of an inch of wear can throw off your engine’s performance.

The camshaft works by converting rotational motion into linear motion. As it spins (at half the speed of your crankshaft in four-stroke engines), the lobes push against followers, which then actuate your valves. The shape of each lobe determines:

- When the valve opens (timing)

- How far it opens (lift)

- How long does it stay open (duration)

- How quickly it opens and closes (ramp rate)

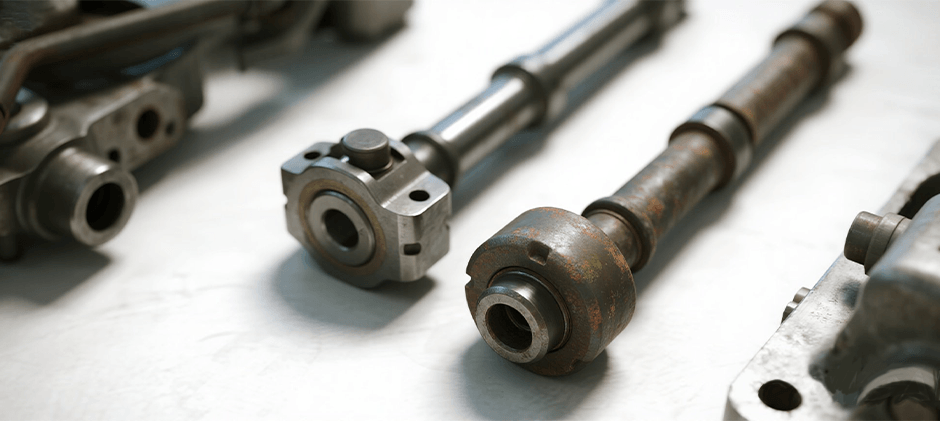

Modern camshafts are typically made from cast iron or forged steel, with the cam lobes either induction hardened or chill-cast for wear resistance. The surface hardness might reach 50-60 Rockwell C, but this hard layer is often only .050-.100 inches deep. Once you wear through that hardened surface, the softer material underneath wears rapidly – that’s when things go south fast.

“A camshaft is like a marriage – it needs to work perfectly with its partner (the followers) or things get ugly quick,” jokes one engine builder. “And just like a marriage, lack of lubrication causes most of the problems!”

10 Common Signs of Camshaft Lobe Wear

Before we dive into causes, let’s talk about how your engine tells you the camshaft is wearing out. Catching these symptoms early can mean the difference between replacing just a camshaft and rebuilding your entire top end.

Early Warning Signs:

- Loss of power: Worn lobes don’t open valves fully, reducing airflow

- Rough idle: Uneven valve timing causes combustion inconsistencies

- Increased fuel consumption: Poor valve timing hurts efficiency

- Hard starting: Compression suffers when valves don’t seal properly

- Engine misfire: Especially noticeable under load

Advanced Symptoms:

- Loud ticking or tapping: Metal-on-metal contact as clearances increase

- Backfiring: Exhaust valves not closing completely

- Blue or white smoke: Oil burning from valve guide wear

- Check engine light: Modern engines detect timing variations

- Complete valve train failure: The worst-case scenario

One fleet mechanic shared this wisdom: “When drivers complain their truck ‘just doesn’t pull like it used to,’ I head straight for the valve cover. Nine times out of ten, I find worn cam lobes. The engine compensates for a while, but eventually, you can’t hide worn lobes.”

The tricky part? Cervicogenic wear often happens gradually. You might not notice the slow power loss until one day you realize your engine needs to downshift on hills it used to climb easily. That’s why regular valve adjustments aren’t just maintenance – they’re inspection opportunities.

Oil-Related Causes of Premature Wear

If we had to pick the number one killer of camshafts, it’s oil – or more specifically, the lack of proper lubrication. Your camshaft operates under extreme pressure where the lobes meet the followers, creating metal-to-metal contact that only a thin film of oil prevents from becoming destructive.

Oil Starvation Issues:

The camshaft is often one of the last components to receive oil, especially on cold starts. Oil must travel from the pump, through the filter, up through galleries, and finally to the cam bearings and lobes. Any restriction along this path spells trouble:

- Clogged oil passages from sludge buildup

- The worn oil pump is losing pressure

- Restricted oil filters from extended change intervals

- Low oil level is starving the system

Wrong Oil Viscosity:

Using oil that’s too thin won’t maintain the protective film under high pressure. Too thick, and it won’t flow quickly enough during cold starts. “I’ve seen guys run 5W-30 in old diesels to save fuel,” notes one technician. “Sure, they saved a few gallons of diesel, but they bought new camshafts at 200,000 miles instead of 500,000.”

Oil Quality and Additives:

Modern diesel oils contain zinc dialkyldithiophosphate (ZDDP), an anti-wear additive crucial for flat-tappet cam survival. But here’s the catch – newer low-emission oils have reduced ZDDP levels. If you’re running an older diesel with flat tappets, you need oil with adequate ZDDP levels (1,200-1,400 ppm), not the 600-800 ppm in modern oils.

Oil Change Intervals:

Extended drain intervals might save money short-term, but worn camshafts cost more than a few oil changes. Contaminated oil acts like liquid sandpaper, accelerating wear on those precision-ground lobes.

Mechanical Factors Contributing to Lobe Damage

While oil issues cause many cam failures, mechanical factors play a huge role, too. These are often the result of improper installation, lack of maintenance, or using the wrong parts during repairs.

Incorrect Valve Adjustment:

This is huge – probably the second biggest cam killer after oil problems. When valves are adjusted too tightly, the cam lobes never get a break. They’re under constant pressure, accelerating wear. Too loose isn’t much better, causing impact damage as clearances slam shut.

Follower/Lifter Problems:

Your cam lobes are only half the equation – they work with followers (also called lifters or tappets). Common follower issues include:

- Stuck lifters: Usually from sludge or varnish buildup

- Worn follower faces: Create uneven contact with cam lobes

- Mismatched components: Using the wrong followers for your cam profile

- Failed roller bearings: In roller follower applications

Spring Pressure Issues:

Valve springs that are too weak allow valve float at high RPM, slamming valves shut, and shock-loading the cam lobes. Springs that are too stiff create excessive pressure, accelerating wear. “Spring pressure is like Goldilocks,” explains one engine builder. “Not too soft, not too hard – it needs to be just right.”

Timing Chain/Gear Wear:

As timing chains stretch or gears wear, cam timing retards. This doesn’t directly wear the lobes, but it masks developing problems and can lead to piston-to-valve contact if severe enough. Plus, the slack in worn timing components creates harmonics that accelerate cam bearing wear.

Installation Errors:

We see this more than you’d think – cams installed without proper break-in procedure, inadequate assembly lube, or contamination during installation. One speck of dirt during assembly can score a lobe beyond repair.

Environmental and Operational Factors

How you operate your engine has a massive impact on camshaft life. Two identical engines can have vastly different cam wear based solely on how they’re used and maintained. Let’s look at the operational factors that separate 100,000-mile cams from million-mile survivors.

Cold Start Damage:

Those first few seconds after starting are critical. Oil hasn’t reached the cam lobes yet, and metal-on-metal contact is occurring. Engines that see frequent cold starts – delivery trucks, emergency vehicles, equipment with lots of start-stop cycles – experience accelerated cam wear. “Every cold start ages your cam like 500 miles of highway driving,” warns one fleet manager.

Operating Temperature Extremes:

Running too cold is worse than running hot for cam wear. Cold engines mean thick oil that doesn’t flow well, plus increased fuel dilution washing oil off critical surfaces. Engines that never reach full operating temperature – think farm equipment used for short tasks – often show premature cam wear.

Contamination Issues:

- Fuel dilution: Unburned diesel washes oil off cam lobes

- Coolant contamination: Destroys oil’s lubricating properties

- Dirt ingestion: Acts like grinding compound on cam surfaces

- Soot loading: Common in engines with EGR problems

Load Factors:

Engines consistently operated under heavy loads experience higher valve spring pressures and temperatures, accelerating wear. But light-load operation isn’t ideal either – engines need some load to maintain proper operating temperature and burn clean.

Idle Time:

Excessive idling is a cam killer. Oil pressure drops at idle, reducing flow to the camshaft. Plus, idling engines run cool, increasing fuel dilution and soot loading. “If I could ban one thing to extend engine life, it would be unnecessary idling,” states one experienced mechanic.

Diagnostic Techniques for Cam Wear Assessment

Catching cam wear early requires knowing what to look for and having the right inspection techniques. You don’t always need fancy equipment – sometimes your senses and basic tools tell the story.

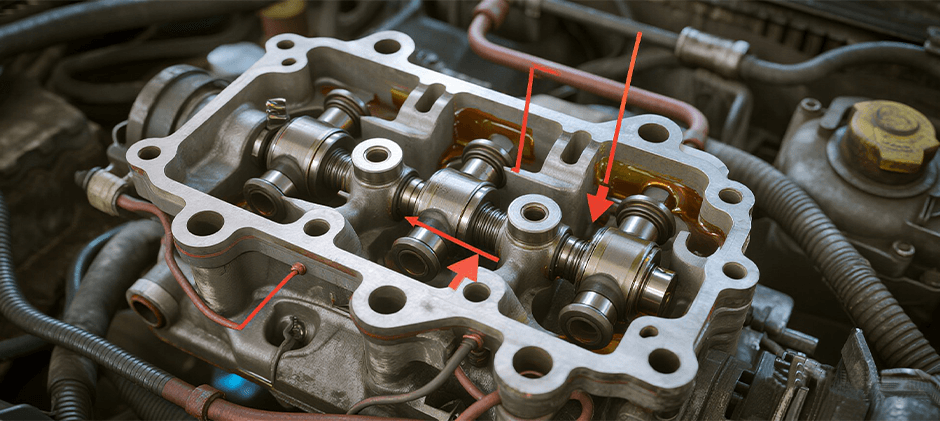

Visual Inspection Methods:

When you pull a valve cover, look for:

- Lobe shape: Worn lobes appear flattened or concave

- Surface finish: Good lobes are mirror-smooth; worn ones show pitting

- Discoloration: Blue or purple indicates overheating

- Metal transfer: Shiny deposits suggest severe wear

Measurement Techniques:

- Dial indicator method: Measure actual valve lift vs specifications

- Micrometer checks: Measure lobe height directly

- Cam doctor or profile gauge: For checking the complete lobe profile

- Endoscope inspection: Check lobes without disassembly

Performance Testing:

- Compression test: Worn intake lobes reduce compression

- Cylinder leakage test: Identifies valve sealing issues

- Vacuum gauge readings: Erratic needle indicates valve problems

- Power balance test: Identifies weak cylinders

“The best diagnostic tool is your ear,” shares a veteran diesel tech. “Each engine has its own sound when healthy. When that rhythm changes, something’s wrong. Worn cams create a distinctive ‘lazy’ tapping – once you hear it, you never forget it.”

Oil Analysis Clues:

Lab analysis can detect cam wear before you hear it:

- Increased iron levels indicate wear

- Chrome suggests ring or liner wear

- Copper and lead point to bearing issues

- Aluminum might indicate piston problems

Prevention Strategies and Best Practices

Now for the good news – most camshaft failures are completely preventable. With proper maintenance and operating practices, your cam should last the life of the engine. Here’s how to keep those lobes happy and healthy.

Oil System Maintenance:

- Use the right oil: Check the manufacturer specs for viscosity and additives

- Change oil religiously: Don’t push intervals, especially in severe service

- Quality filters only: Cheap filters mean expensive repairs

- Check oil level daily: Low oil kills cams fast

- Fix leaks immediately: Can’t lubricate what isn’t there

Operational Best Practices:

- Warm up properly: Give oil time to reach the cam before heavy loads

- Avoid excessive idling: Shut down instead of idling for hours

- Maintain operating temperature: Thermostats aren’t optional

- Clean air and fuel: Contamination accelerates wear

- Regular valve adjustments: Catch problems early

Break-In Procedures for New Cams:

- Use high-ZDDP break-in oil or additive

- Apply assembly lube liberally during installation

- Vary the RPM during the first hour of operation

- Change oil after the break-in period

- Check valve adjustment after break-in

Component Matching:

- Always replace followers with cam

- Verify spring pressures match the cam profile

- Use the correct pushrods for the application

- Ensure timing components are in spec

“Prevention is like insurance,” notes one shop owner. “You pay a little up front in maintenance to avoid paying a lot later in repairs. I’ve never met anyone who regretted taking care of their engine.”

When to Replace vs Repair Camshaft Components

Making the right call on cam replacement can save money and prevent future problems. Sometimes you can get away with replacing just followers; other times, the whole valve train needs attention. Here’s how to make smart repair decisions.

When Camshaft Replacement is Necessary:

- Lobe lift loss exceeds 0.010 inches

- Visible pitting or spalling on lobes

- Cam bearing journals show wear

- Multiple lobes affected

- Over 500,000 miles on the original cam

Component Replacement Guidelines:

- Always replace followers with cams: Worn followers destroy new cams

- Check valve springs: Replace if pressure is out of spec

- Inspect pushrods: Look for wear patterns or bending

- Examine rocker arms: Wear accelerates with worn cams

Cost Considerations:

| Component | Part Cost | Labor Hours | Total Estimate |

| Camshaft only | $300-800 | 8-12 | $1,500-2,500 |

| Cam & followers | $500-1,200 | 10-14 | $2,000-3,500 |

| Complete valve train | $1,000-2,500 | 15-20 | $3,500-6,000 |

Upgrade Opportunities:

When replacing a worn cam, consider:

- Performance profiles for more power

- Roller conversion for reduced friction

- Billet cams for extreme applications

- Updated profiles for better fuel economy

“Don’t penny-pinch on cam replacement,” advises one engine builder. “Labor is the big cost. Spending an extra $200 on quality parts is nothing compared to doing the job twice.”

Protecting Your Camshaft Investment

Your camshaft works tirelessly, orchestrating the complex dance of valves that keeps your engine running. When it wears out prematurely, it’s usually because we didn’t hold up our end of the maintenance bargain. The good news? With proper care, a quality camshaft should last the life of your engine.

At FridayParts, we’ve seen every type of cam failure imaginable over our 16 years in business. We stock camshafts, followers, and complete valve train components for all major diesel brands – CAT, Cummins, Detroit, Perkins, and more. But we’d rather help you prevent cam failure than replace worn parts.

Remember these key points:

- Oil is everything – quality, quantity, and regular changes

- Valve adjustment isn’t optional – it’s preventive maintenance

- Operating conditions matter – treat your engine right

- Early detection saves money – don’t ignore the warning signs

- Quality parts pay for themselves – cheap cams wear fast

Whether you’re maintaining a fleet of trucks or keeping your trusty tractor running, understanding camshaft wear helps you make better decisions. Because when Friday night rolls around, we want you relaxing with that cold beer, not dealing with engine problems.

Fix it once, fix it right – with proper maintenance and quality parts, your camshaft will keep perfect time for hundreds of thousands of miles.

Need camshaft or valve train components? FridayParts stocks thousands of OEM-quality parts for all major diesel engines. From complete camshaft kits to individual followers, we’ve got what you need. With worldwide shipping and expert support, we’re here to keep your engine running strong. Visit FridayParts.com – your trusted partner in diesel parts for over 16 years.