When temperatures drop and work sites turn icy, traction becomes the difference between steady productivity and downtime. Every operator who relies on a skid steer track system during the winter knows that standard treads struggle to grip on frozen ground. In this guide, we’ll break down how to choose the right tracks for your machine, which types work best on different terrains, and most importantly, which patterns offer superior traction, stability, and lifespan during the snow and ice season.

Criteria to Select Skid Steer Tracks

Before choosing a new set of tracks, we need to look beyond price and width. Winter conditions add stress that exposes weak materials, poor tread design, and poor fitment.

We recommend evaluating these four main criteria:

1. Terrain Specificity

- Hard or mixed terrain requires narrow tracks for higher ground pressure and grip.

- Snow, mud, or soft terrain needs wider tracks that spread the load for better flotation.

2. Tread Pattern Design

The lug shape and angle determine how your machine interacts with the surface. Winter terrain demands aggressive, self-cleaning tread patterns that cut through snow instead of packing into it.

3. Material Quality and Flexibility

Tracks built from natural–synthetic rubber blends or high-grade compounds maintain elasticity in freezing temperatures. Brittle rubber loses grip fast.

4. Reinforcement and Durability

Steel cords, Kevlar lining, and reinforced sidewalls matter when operating on rock, ice, or frozen ruts. They prevent elongation and premature tearing from cold brittleness.

A quick checklist for operators:

| Factor | What to Look For | Winter Impact |

|---|---|---|

| Rubber compound | Cold-flexible blend | Prevents cracking |

| Lug pattern | Directional or multi-edge | Improved traction |

| Self-cleaning channels | Deep angled grooves | Keeps snow from packing |

| Reinforcement | Steel cords or Kevlar | Prevents stretch & tearing |

The Best Tracks for Skid Steers for Different Terrains

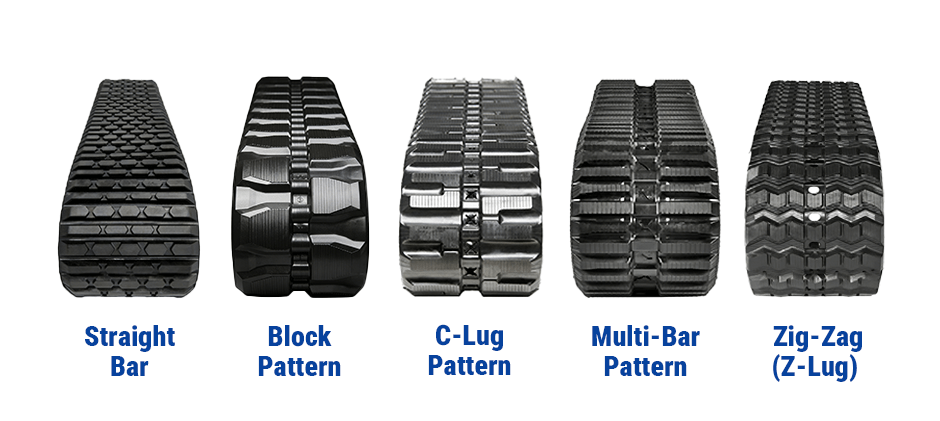

Choosing the right skid steer track isn’t only about snow—it’s about matching the tread to your most common environment. Let’s briefly explore key tread styles and where they excel.

| Tread Type | Typical Design | Best For | Drawback |

|---|---|---|---|

| Straight Bar | Continuous straight ribs | Wet clay, mud | Limited side traction |

| Block Pattern | Square blocks, thick rubber | Hard or rocky surfaces | Poor snow grip |

| C-Lug Pattern | C-shaped staggered lugs | Mixed jobsites (dirt/snow/gravel) | Average cleaning ability |

| Multi-Bar Pattern | Multiple linear bars | Loose soil, mild snow | Mud packing possible |

| Zig-Zag (Z-Lug) | Sharp, interlocking Z shape | Snow, ice, and slush | Slightly rough ride on asphalt |

For operators in landscaping, agriculture, or mixed construction environments, C-lug and multi-bar are reliable all-season options. They balance traction and surface care.

However, for freezing climates or snow removal tasks, Zig-Zag tracks dominate due to their directional traction pattern and self-cleaning ability—qualities we’ll explore further below.

Best Skid Steer Tracks for Winter Conditions

Winter’s combination of snow, slush, and refreezing ice pushes skid steers to their traction limits. The right track can transform the machine’s behavior—reducing wheel slip, improving pushing power, and cutting control losses on slopes.

Here are the top-performing skid steer tracks for winter operations on off-road machinery:

1. Zig-Zag (Z-Lug) Skid Steer Tracks

The leading choice for snow performance.

Zig-Zag or Z-Lug tracks use an aggressively cut, multi-angled tread that cuts into snow while ejecting buildup. The Z-shaped pattern produces continuous biting edges—ideal for packed snow and ice.

Key Benefits:

- Exceptional Grip on Ice: Numerous angled edges increase shear resistance.

- Self-Cleaning: Open grooves push out snow and slush.

- Directional Control: High traction in forward and reverse motion.

- Slope Stability: Balanced pressure reduces fishtailing on hills.

In a side-by-side test with traditional straight-bar tracks, Z-lug designs showed up to 30% shorter stopping distance on packed snow. That grip translates directly into better safety and productivity.

2. Multi-Bar Tracks

Sometimes known as “all-terrain” tracks, these use repetitive low-profile bars that maintain consistent ground contact.

In winter, multi-bar tracks offer predictable handling on mixed snow and dirt surfaces, which makes them ideal for transitional climates or areas with freeze–thaw cycles.

Highlights:

- Smooth ride with even traction

- Moderate self-cleaning

- Gentle on sensitive ground (pavement, turf)

They’re a good compromise if your machine switches between icy roads and muddy worksites.

3. Terrapin or TDF Multi-Bar Hybrid Tracks

These features have nearly continuous tread edges that grab the surface instead of digging into it—critical for ice. Their linear bar alignment maximizes the contact patch, reducing slip during turns or when carrying heavy loads on frozen surfaces.

Advantages:

- Linear edge design for superior ice traction

- Reduced vibration for cab comfort

- Suitable year-round in wet, soft, or frozen ground

A Terrapin/TDF hybrid is especially effective for snow removal and utility operations where idle time is costly.

Traditional Skid Steer Tracks Used in Snow

Before the rise of directional Z-patterns, operators mostly used C-lug or block-pattern tracks. While these still serve as general-purpose options, they fall short on snowpack and ice.

- C-Lug Tracks: Provide fair traction but tend to “dig” into soft snow instead of gripping it. This can lead to excessive ground disturbance and poor stability.

- Block Tracks: Solid performance on asphalt or concrete but limited grip on ice. Their heavy rubber mass offers durability at the cost of self-cleaning.

These traditional skid steer tracks still see use in mild winter climates, but struggle in subzero conditions where snow turns into polished ice. For most off-road professionals, upgrading to modern directional treads is a practical performance investment.

Selecting Tracks for Your Fleet: Practical Buying Guide

Once we’ve matched tread style to terrain, fleets still need a repeatable way to buy tracks that won’t cause avoidable downtime. For most snow work, we should standardize around:

- The winter surface we see most (packed snow/ice vs slush vs mixed gravel),

- The load and push demands of each route, and

- The machine’s exact track specs (pitch, width, and overall length).

As a quick summary: choose Zig-Zag (Z-Lug) for the most bite and self-cleaning in real winter conditions; choose Terrapin/TDF hybrids for strong ice contact and smoother driving; choose multi-bar for mixed ground and frequent transitions.

From a fleet purchasing view, it helps to source both tracks and related snow removal equipment parts from one place so we can keep consistent fitment records and reduce lead times during peak season. Suppliers like FridayParts support this approach by offering aftermarket options across many equipment brands, which makes it easier to standardize replacements, stock the right spares, and keep machines moving when storms hit.

Fleet selection checklist (use this before placing an order):

- Confirm OEM dimensions (pitch, width, link count/length) for each machine model.

- Pick tread by route reality (ice-heavy lots and slopes → directional Z patterns; mixed sites → hybrid or multi-bar).

- Choose a cold-flexible rubber compound and reinforced construction for freeze–thaw abuse.

- Align on one or two tread styles across the fleet to simplify stocking and training.

- Buy early if you see cracking, cord exposure, or rounded lugs—waiting often adds drivetrain stress and emergency labor.

Maintenance Tips for Winter Longevity

Cold weather doesn’t just affect traction—it accelerates rubber wear and metal fatigue. Simple maintenance can double your track life:

- Check tension weekly: Cold contraction can change the tension level.

- Clean tracks daily: Ice accumulation under sprockets can cause de-tracking.

- Store indoors if possible: Frozen rubber stiffens and cracks more easily.

- Inspect steel cords: Rust and moisture in cold climates weaken the internal structure.

Preventive care ensures your investment in winter tracks continues paying off through multiple seasons. If you’re also comparing the best skid steer for snow removal, remember that the machine’s pushing power only shows up when the tracks can actually transfer it to the ground.

Table: Recommended Winter Tracks at a Glance

| Track Type | Traction | Ride Comfort | Surface Compatibility | Best Use |

|---|---|---|---|---|

| Zig-Zag (Z-Lug) | ★★★★★ | Moderate | Snow, ice, mud | Heavy snow removal & steep slopes |

| Terrapin / TDF | ★★★★☆ | High | Ice, soft snow, slush | Utility, all-weather performance |

| Multi-Bar | ★★★★☆ | Very High | Light snow, mixed terrain | Transitional seasons |

| C-Lug | ★★★☆☆ | High | Mixed terrain | Mild winter, general use |

| Block | ★★☆☆☆ | Low | Hard surfaces | Urban sites, no heavy snow |

Final Words

Upgrading to a winter-optimized skid steer track is more than a traction boost—it’s a safety decision and a productivity multiplier. Modern directional treads like Zig-Zag and Terrapin provide the control, power, and reliability needed when efficiency can’t take a snow day. If your off-road machine is struggling through icy shifts, it’s time to switch to high-quality winter tracks designed to meet OEM standards without high costs. FridayParts offers a vast inventory of aftermarket skid steer parts engineered for heavy equipment brands across the industry. With proven quality, wide compatibility, and affordable pricing, it’s easier than ever to prepare your fleet for winter and beyond.