If you’re looking to replace your equipment’s ball joints but are hesitant to decide due to the wide range of prices on the market, or if you need a more comprehensive price guide, this article is perfect for you. This guide provides a clear and practical analysis of the cost of replacing an off-highway equipment ball joint in 2025, the factors that influence price, and the information you need to make an informed decision.

Key Point

For individuals whose financial capacity is under consideration, or who pursue the utmost value, the following aspects merit attention:

- Aftermarket Parts Offer Savings: Aftermarket ball joints of superior fabrication possess the same form, fit, and function as those of OEM origin, yet demand only a modest portion of the expenditure.

- FridayParts Pricing: At FridayParts, our substitute ball joints applicable to a diverse array of heavy equipment are generally positioned within the interval of $19 to $135 per unit.

- Informed Choice: The selection of aftermarket components enables one to markedly diminish the totality of repair costs, particularly when one is endowed with the service of a reliable independent mechanic or the capability to execute the labor by oneself.

What Are Ball Joints?

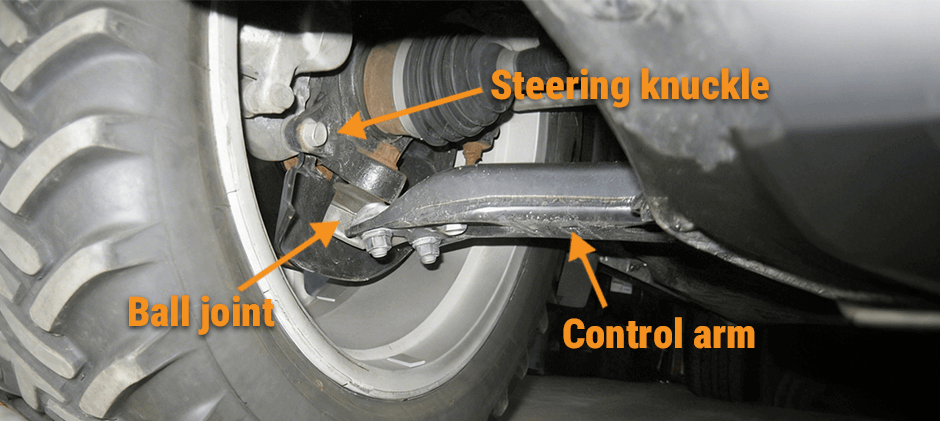

Unlike those small vehicle ball joints, the ball joints on heavy-duty machinery such as skid steers, backhoes, or telehandlers are constructed with great endurance to bear tremendous stress. In essence, a ball joint is a flexible connection in the form of a ball and socket, resembling the structure of a human hip. It is composed of a metallic casing (serving as the socket) and a ball stud that performs both rotational and pivotal movements inside.

This seemingly simple structure accomplishes two indispensable functions:

- It functions as a rotational pivot, permitting the wheels to direct toward the left or the right.

- It enables the suspension to execute vertical motion, thus mitigating the severe jolts arising from irregular or rugged terrain at work sites.

In the absence of properly operating ball joints, the machine’s steering mechanism would cease to function, and the entire wheel assembly would lose its steadiness. They serve as the essential axis that secures the integrity of the front suspension system.

How Much to Replace Ball Joints?

The total cost to replace ball joints is a combination of part cost and labor. Labor is often the largest part of the expense, as the job can be intensive. Below is a table with estimated costs for common types of off-road machinery.

| Machine Type | Aftermarket Part Cost (Per Joint) | OEM Part Cost (Per Joint) | Estimated Labor Hours (Per Joint) | Estimated Total Aftermarket Cost | Estimated Total OEM Cost |

|---|---|---|---|---|---|

| Skid Steer Loader | $40 – $90 | $150 – $300 | 2 – 3 hours | $240 – $490 | $350 – $900 |

| Backhoe Loader | $60 – $135 | $250 – $500 | 2.5 – 4 hours | $310 – $735 | $500 – $1,300 |

| Telehandler | $75 – $150 | $300 – $600 | 3 – 5 hours | $375 – $950 | $600 – $1,600 |

| Compact Wheel Loader | $80 – $160 | $350 – $700 | 3 – 5 hours | $380 – $960 | $650 – $1,700 |

For those maintaining older off-road machines, sourcing aftermarket ball joints can significantly reduce total costs while maintaining quality. Most parts cost much less than what you’ll find on the market. FridayParts sets ball joint prices according to raw materials and basic costs, ranging from $19 to $135 to ensure both price and quality. Midway through your purchasing research, browse transmission & undercarriage parts to compare compatible assemblies that often pair with suspension or steering maintenance.

How Long Does a Ball Joint Replacement Require?

On average, replacing a single ball joint takes between 1–3 hours. Machines with press‑fit assemblies or restricted access may require extra disassembly time. Alignments or steering recalibration add an hour.

- 1 hr: Simple bolt‑on joint

- 2–3 hrs: Press‑in or encapsulated design on large loaders

- +1 hr: Post‑replacement alignment and safety inspection

Scheduling multiple joint replacements together can lower total labor costs, as technicians can complete both sides with fewer setup changes.

Factors Affecting Ball Joint Replacement Cost

Several variables can influence the final invoice for your repair.

- Machine Make, Model, and Year: Parts for popular, high-volume machines are often more readily available and affordable. Obscure or older models may have more expensive or harder-to-find parts.

- Part Source (OEM vs. Aftermarket): As shown in the table, this is the single biggest factor in part cost. High-quality aftermarket ball joints deliver reliable performance for a much lower investment.

- Labor Rates: Dealerships typically have the highest labor rates, followed by independent heavy equipment repair shops.

- Job Complexity: Some ball joints are bolted on and are relatively easy to replace. Others are pressed into the control arm and require special hydraulic presses and tools, increasing labor time. Severe rust and corrosion can also make the job much more difficult and time-consuming.

- Additional Repairs: A failed ball joint often puts extra stress on surrounding components. It is common to replace tie rod ends or other worn bushings at the same time. While the suspension is disassembled, it’s a cost-effective moment to inspect all transmission & undercarriage parts for wear. We also highly recommend doing a wheel alignment after the replacement to prevent premature tire wear.

When To Replace Heavy Equipment Ball Joints?

Ball joints do not have an exact lifespan, but for most off-road machinery, it is considered necessary to conduct inspections every 500–1,000 working hours. Replacement commonly occurs within 2,000–5,000 hours, with the precise timing influenced by labor intensity and the sufficiency of lubrication.

Watch for the following signs of bad ball joints:

- Audible clunking or knocking noises during steering or while crossing uneven terrain

- Perceptible vibration transmitted through the steering lever or wheel

- Irregular tire wear implies the occurrence of misalignment

- Steering response is becoming loose, unstable, or drifting

- When you lift the axle and shake the wheel, you may notice looseness or wobbling.

- Abundant grease exudation or ruptured dust boots

To persist in operating machinery with defective ball joints (or with loosened pivot points) shall aggravate the wear of control arms, steering knuckles, and tires, thereby causing the expenditure on repair to increase in swift multiplication.

Can You Replace Ball Joints at Home?

Replacing ball joints isn’t impossible for skilled operators, but for off‑road machinery, the process can be physically demanding and tool‑intensive. Proper lifting, torque specifications, and alignment setup are vital for safety.

DIY replacement may be feasible if you have:

- A ball joint press kit

- Heavy‑duty hydraulic jacks

- Proper service manuals

- Safety stands support the weight of your machine.

Typical DIY Steps

- Safely raise and support the machine’s front end.

- Remove tires, brake lines, and steering linkage.

- Use a press to remove old joints.

- Clean the seat and insert a new ball joint.

- Torque bolts to manufacturer specs and re‑check play.

If any step feels uncertain, it’s worth hiring a certified mechanic. Improper installation can lead to premature wear or sudden steering failure. Remember — a poor repair on heavy machinery has consequences more serious than on a car.

Summary

Replacing ball joints is critical for steering safety and control precision. With part prices steadily rising in 2025, choosing the right supplier matters more than ever.FridayParts offers a full range of ball joints, steering kits, and transmission & undercarriage parts for off‑road machinery at $19–$135, combining affordable pricing with proven durability. Whether you operate loaders, tractors, or dump trucks, maintaining joint integrity ensures smoother operation, less downtime, and lower lifecycle costs.