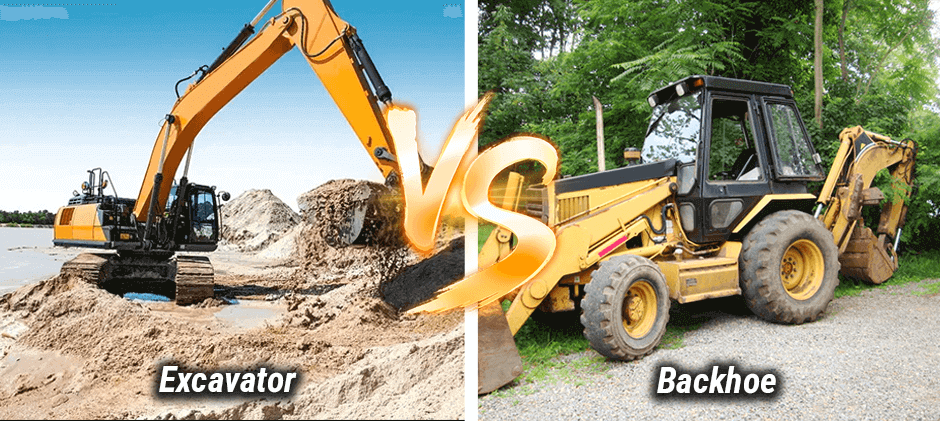

Backhoes and excavators are two common types of construction equipment, but they’re often mistaken for similar functions or simply confused. If you’re confused about the differences between the two and don’t know which one to choose for your project, read on for this guide. This guide aims to eliminate such doubt. We will conduct a detailed and positive comparison of backhoe and excavator, analyzing their respective advantages and disadvantages, and explaining common project scenarios, so as to help you confidently choose the machine suitable for your work.

What Is a Backhoe and Excavator?

At first glance, these two machines may appear very similar—they both are equipped with a boom, a digging bucket, and a loader bucket for excavation. However, they are completely different tools, and their design concepts are entirely distinct.

What is a Backhoe?

The backhoe is the “Swiss army knife” of the construction industry. It is based on a standard tractor chassis and possesses dual functions:

Rear: an excavating arm with a bucket, called a backhoe. Its name comes from the digging action—pulling the soil back to the machine.

Front: a large loader bucket, very suitable for pushing, lifting, and moving materials.

The driver’s seat can rotate 180–200 degrees, facilitating the user to switch control between the front loader and the rear excavating arm. This dual-use design makes its function versatile, capable of executing various tasks.

What is an Excavator?

The excavator is a kind of professional digging machine. Different from the backhoe (a tractor with attachments), the excavator is specially designed for one main function: powerful digging capacity. Its main characteristics include:

360-degree rotation: the entire cabin, boom, and dipper assembly (“house”) can rotate 360 degrees on the chassis.

Tracked or Wheeled Undercarriage: Most excavators are adopting the crawler wheeled undercarriage, which can provide excellent stability on rugged or soft terrains. This design allows the excavator to remain stationary while performing digging, lifting, and dumping operations over a wide surrounding area, thereby efficiently completing large-scale earthmoving works.

Detailed Comparison of Backhoe and Excavator

Although backhoes and excavators may share a common goal — moving soil, their designs for achieving this goal are starkly different. These distinctions in size, maneuverability, and function are not merely technical details; they are the decisive factors determining which machine can make your project successful, and which machine may become a costly bottleneck. Let us analyze in detail the distinctions between them.

1. Size, Weight, and Raw Power

The most immediate distinction lies in their volume. The excavator is designed for heavy lifting and large-capacity digging, hence its volume and weight are significantly increased. This weight is not for show, but lays the foundation for a more powerful engine and hydraulic system, thereby delivering a stronger digging force to penetrate hard ground or rock. In contrast, the backhoe uses a lighter agricultural tractor chassis. While in terms of size, the backhoe possesses strong power, its formidable force cannot be equated with the excavator. However, this lighter weight serves as a critical advantage on refined pavements or soft ground, because the heavy tracks of the excavator would cause serious damage to such surfaces.

2. Rotation and Work Efficiency

This is the biggest difference in these machines’ operating methods. The backhoe’s digging arm is installed on a pivot, allowing it to swing approximately 200 degrees of arc. To operate beyond this arc, the operator must readjust the entire machine’s position. However, the excavator has on its chassis an “upper structure” (cab, engine, and arm assembly) capable of 360-degree rotation. This allows the operator to dig in front of the machine, scoop at the side, and dump materials directly behind the machine without moving the tracks. For repetitive tasks such as loading trucks or continuous trenching, this full rotation has a tremendous advantage in speed and efficiency.

3. Mobility and On-Site Transport

How the machine arrives at the construction site is a critically important factor for logistics and financial considerations. The backhoe loader is equipped with a wheeled chassis, which can travel on public roads at speeds up to 25 miles per hour. This “start-and-go” capability is very valuable for contractors handling multiple tasks at different locations, because it does not require a transport trailer. Most excavators adopt a tracked movement, which does not comply with road regulations. They are machines for construction site operation and must be transported with low-bed trailers, which brings tremendous cost, time, and planning burden to any project.

4. Stability on Uneven Ground

Excavators’ wide tracked chassis gives them a low center of gravity and a large footprint, thereby providing excellent stability, especially on slopes or soft and uneven terrain. This makes it safer when lifting heavy objects or operating on challenging ground. The backhoe loader adopts a wheeled chassis with a higher center of gravity. It relies on deploying stabilizer legs to create a firm digging platform, but it still cannot match the inherent stability of tracked excavators.

Pros and Cons of Backhoe and Excavator

Let us extract the above comparison into a clear list of advantages and disadvantages.

Backhoe: Multi-functional All-rounder

Advantages:

- Multi-function: Combines the functions of an excavator and loader in one.

- Mobility: Can travel on roads, saving the local operation transport cost.

- Lower cost: Usually purchase price and operation cost are lower.

- Maneuverability: Compact size, very suitable for narrow working sites.

Disadvantages:

- Insufficient power: Excavation force or lifting capacity cannot match the excavator.

- Limited reach and depth: Not suitable for deep or large-scale digging.

- Restricted rotation: 200-degree rotation efficiency is lower than the excavator’s 360-degree rotation.

Excavator: Powerful Specialist

Advantages:

- Strong power: Unmatched digging force, can easily penetrate hard ground.

- Excellent reach and depth: Can dig deeper and farther than any backhoe.

- Superior stability: Tracks provide a solid platform on almost any terrain.

- High efficiency: 360-degree rotation design enables fast digging and loading.

Disadvantages:

- Poor mobility: Requires truck and trailer transport, increasing cost and logistic burden.

- Higher cost: Purchase, maintenance, and fuel expenses are higher.

- Limited functionality (out-of-the-box): It mainly is a digging tool, without the loader function.

Which One is Right for Your Project?

Now, let us apply this knowledge to practical scenarios. The best machine is always the one most suitable for specific work.

Suitable for Farms and Agriculture

The backhoe loader, in this regard, undoubtedly is the king. Its outstanding mobility allows it to move within large sites without a trailer. The front loader is very suitable for transporting hay, feed, and materials, while the rear digging arm can handle digging drainage ditches, clearing tree stumps, and cleaning fences.

Suitable for Large Construction and Demolition

The excavator is the only choice for these heavy-duty works. Excavating large foundations requires a powerful force, and their stability and reach are crucial for safe demolition of buildings. Equipped with a hydraulic hammer or grapple, the excavator will become a powerful demolition force. These works bring great stress to the machine, which means having reliable and durable excavator parts sources is very important to ensure the project proceeds according to plan.

Landscaping and Utilities

These projects usually are in a gray area, but the backhoe usually has more advantages. It is lighter in weight, less likely to damage finished surfaces such as lawns and driveways. It can dig a trench, then immediately backfill with the front loader, which makes it very efficient for laying pipelines or cables. For large landscaping projects requiring the placement of heavy stones or the digging of pools, a small excavator may be more suitable.

Mining and Quarrying

This is the advantage of excavators. These projects require continuous moving of large amounts of soil and rocks. The power, durability, and large-capacity bucket of the excavator are exactly designed for this high-intensity work. Continuous grinding work is very hard for the machine’s undercarriage; therefore, maintaining the undercarriage components is the primary task to avoid costly downtime.

FAQs

1. Can you use a backhoe for major excavation?

While a backhoe can excavate, it’s best suited for small to moderate projects, like digging a residential basement or a trench. For major, deep excavation, its limited power and reach make it far less efficient than an excavator.

2. What is a “Trackhoe”?

“Trackhoe” is a common nickname for an excavator. It arose because the machine functions like the “hoe” part of a backhoe but runs on tracks. Functionally, the terms “excavator” and “trackhoe” are interchangeable.

3. What is the main difference in the operator’s controls?

Backhoe controls often come in a two-lever “joystick” pattern. The operator’s seat physically swivels to face the rear controls. Excavator controls are also joystick-based, but they control both the boom/arm and the 360-degree swing of the entire machine house from a fixed forward-facing position.

4. My project involves both digging and moving lots of material on paved surfaces. What should I choose?

This is the classic scene for the backhoe excavator to fully display its capability. It possesses the ability to travel on the road and is equipped with a built-in front loader, making it perfectly suitable for such tasks without requiring a second machine or transport vehicle.

The Final Verdict

Now, you should already understand how to choose a suitable excavator and backhoe excavator for your project. The backhoe excavator is diverse and maneuverable, ideal for agriculture, small construction, and public utilities. The excavator is designed for heavy digging, demolition, and mining operations. By carefully assessing project scale, terrain and required tasks, you can make a wise decision, maximize productivity and reduce costs. Regardless of which one you choose, please maintain your equipment regularly. For this purpose, FridayParts can provide economical maintenance parts, ensuring the machine you select can keep reliable operation in the coming many years.