Whether you are operating the bulldozer in the cold morning or you are driving the skid steer loader in the deep winter season, the warm cabin not only can bring the feeling of comfort, but also is a very important guarantee of safety. If your cabin is feeling very cold in the winter, and the air is not fresh, this may be because the heater core of the equipment is having a problem. Besides the feeling of not being comfortable, this will also influence your long-time vision and attention. In order to avoid such a situation, this article lists seven signs of the heater core having problems, and also tells you how to confirm and replace the damaged heater core.

What Is a Heater Core and Why Does It Matter?

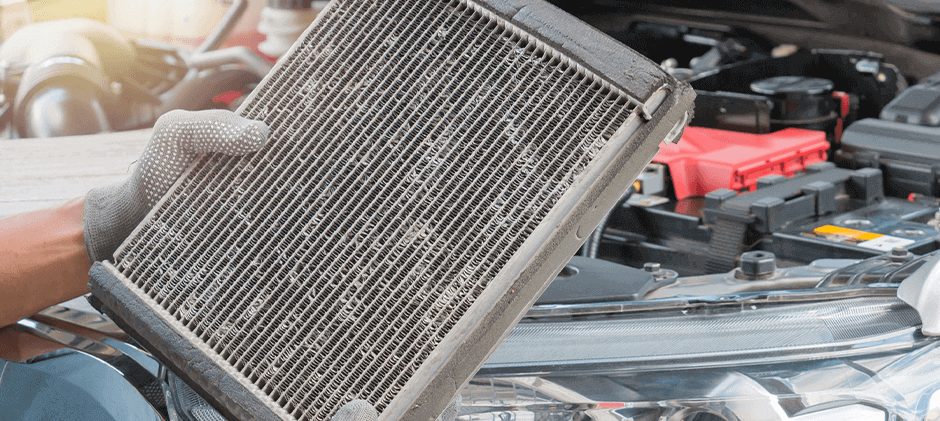

The heater core resembles a radiator on a miniature scale; however, its designated function is not to facilitate the cooling of the engine, but rather to effectuate the heating of the cabin. The cooling system of the engine circulates hot coolant for the purpose of heat dissipation. The cooling system accordingly directs a small fraction of said coolant towards the heater core, which in its fundamental essence consists of a network of pipes and fins situated within the instrument panel of the cabin.

Upon the hot coolant’s passage through these conduits, the blower motor of the cabin propels air across the heated fins of the heater core. Following the air’s acquisition of heat, it is channeled into the cabin via the ventilation orifices. This process serves a dual function of not only maintaining our comfort via warmth, but is likewise of critical importance for the preservation of clarity on the windshield and windows. This is accomplished through the thawing of frost and the preclusion of fog accumulation, thereby enabling us to operate the equipment in a secure manner.

When the heater core fails to function properly, one forfeits both comfort and visual clarity. As individuals in the capacity of operators, it is within our understanding that an unobstructed panorama of the surroundings is of the utmost importance, and when the cabin succumbs to the condition of freezing, our operational efficiency and safety are compromised. Consequently, this underscores the imperative of discerning the symptoms indicative of a clogged heater core.

6 Signs Your Heater Core is Clogged

A clogged heater core doesn’t typically fail overnight. It’s a gradual process, as debris from the cooling system—like rust, scale, or old coolant residue—slowly builds up inside the core’s small tubes. This accumulation restricts the flow of coolant, starving the core of the heat it needs to do its job. We’ve found that paying attention to these six signs can help you diagnose a problem before it becomes a major issue.

1. Weak or No Heat

This is the most direct and most obvious sign. We open the warm wind, but there is no reaction. Even though the engine has already reached the normal working temperature, the wind blowing out from the vent is either almost not hot or completely cold. The fan is running normally, and the blower motor is also making the air flow, but because the heater core is blocked, the air cannot become heated. This problem usually is appearing gradually, so you may will notice that the cabin is becoming more and more uncomfortable during several weeks or even months. This is a classic symptom of a clogged heater core.

2. A Sweet, Sickly Smell

This is a more subtle but more serious sign of a problem. If you are noticing there is a sweet smell inside the cabin, similar to the maple syrup, then very possible that it is the smell of engine coolant. The leakage of the heater core is causing a small amount of coolant to escape, and the blower motor is sending the strange smell out through the vent. Although such a smell is seeming harmless, the coolant is poisonous, and its vapor inhalation is harmful. This sign is showing that the problem is not only blockage, but leakage, and usually it requires the complete replacement.

3. Foggy Windows Inside the Cab

Imagine you’re ready to start your day, and you find a persistent, greasy film or a fine layer of fog covering the inside of your windshield that just won’t clear. This is a common consequence of a leaking heater core. As the hot coolant seeps out, it vaporizes, and this vapor condenses on the cooler surfaces of your windows. This not only significantly reduces visibility but also leaves a difficult-to-clean residue.

4. Constant Coolant Loss

If you constantly top off the coolant reservoir without seeing a visible leak under the machine, the coolant likely disappears into the cab. A leaking heater core can cause a slow, steady loss of coolant, which can also be a safety hazard. This loss can eventually lead to engine overheating.

5. Engine Overheating While the Cab is Cold

This is a critical symptom that signals a major issue with the cooling system. A severely clogged heater core can be a symptom of a much larger problem. If the engine’s coolant flow is so restricted that it can’t circulate properly, the engine may start to run hot, even as the cab remains cold. The lack of heat in the cab and the rising temperature gauge on the dashboard are two signs that something is dangerously wrong with the machine’s cooling and heating systems. A blockage in one part of the system can cause a chain reaction, affecting other components.

6. Fluctuating Cab Temperature

Instead of consistent, warm air, you get intermittent blasts of hot and cold air. This often indicates a partial clog or air pockets in the cooling system. As the coolant struggles to push its way through the partially blocked heater core, the air temperature in the cab can fluctuate wildly, making it impossible to stay comfortable. This is often an early warning sign before a complete failure.

How to Confirm a Clogged Heater Core?

Once one suspects a heater core blockage, there are simple methods to confirm the diagnosis without the need to go deeply into the system.

1. Check Hoses

After the engine is warmed up, one may carefully touch the two heater hoses connected to the firewall. The two hoses should both feel hot. If one hose is hot but the other is only lukewarm or cold, this is a strong sign that coolant cannot flow normally through the heater core.

2. Check for Leaks

Examine for moisture or residue on the foot mats or carpet inside the cabin (especially on the passenger side). A sticky or greasy film is a very clear sign of coolant leaking.

3. Use a Coolant Pressure Tester

A professional-level pressure test can help to find tiny internal leaks that cannot be seen. A sudden drop in pressure may indicate a leak in the heater core or some other part of the cooling system.

How to Fix a Clogged Heater Core?

The method for the rectification of a blocked heater core is contingent upon the severity of the issue at hand.

1. Flushing the Heater Core

For a partial blockage, reverse flushing may be a useful solution. This requires to disconnect the heater hoses and use a garden hose or air compressor to press out water or air in a direction opposite to the normal flow of the coolant. This process can wash away the accumulated debris. However, this is a fine operation that needs caution. Too much force may damage the fragile fins and tubes inside the heater core, so one must operate very carefully.

2. Replacing the Heater Core

If the heater core is seriously blocked or even has a leak, a simple flushing will not work. The only permanent solution is to replace the heater core. While this can be a very time-consuming job, especially on heavy machinery, as the heater core is often deep inside the dashboard, this is the only way to restore its full function and prevent more damage to the cooling system and the inside of the cabin.

When replacing the part, it is crucial to choose a high-quality aftermarket part. We know deeply that reliable parts can handle harsh off-road working conditions. It is not an easy thing to find durable, affordable, and compatible parts for many brands of heavy equipment. FridayParts is proud to be a trusted aftermarket parts supplier. We have a large amount of high-quality parts in our inventory, including heater cores, which meet or even go beyond the original factory specifications, and are at an affordable price.

Conclusion

A heater core of functional capacity is of critical importance for the security and comfort of operating heavy-duty equipment under cold atmospheric conditions. The early discovery of indications of a heater core blockage is capable of precluding significant inconvenience and preventing the machine from suffering costly damage. Irrespective of whether the problem manifests as a gradual leakage, a total absence of heat, or an abnormally diminished level of coolant, timely processing is a matter of crucial importance. The selection of replacement components that are of a reliable and superior quality constitutes the final procedure to ensure your machine’s capability to confront any climatic challenges.