There are quite a few sensors on your equipment, including the crankshaft position sensor (CKP). Like other parts, it can break down over time. If it breaks down, the engine can have all sorts of strange problems. CKP is very critical in engine control, so it is necessary to know the bad crankshaft position sensor symptoms and how to deal with them.

What Is a Crankshaft Position Sensor?

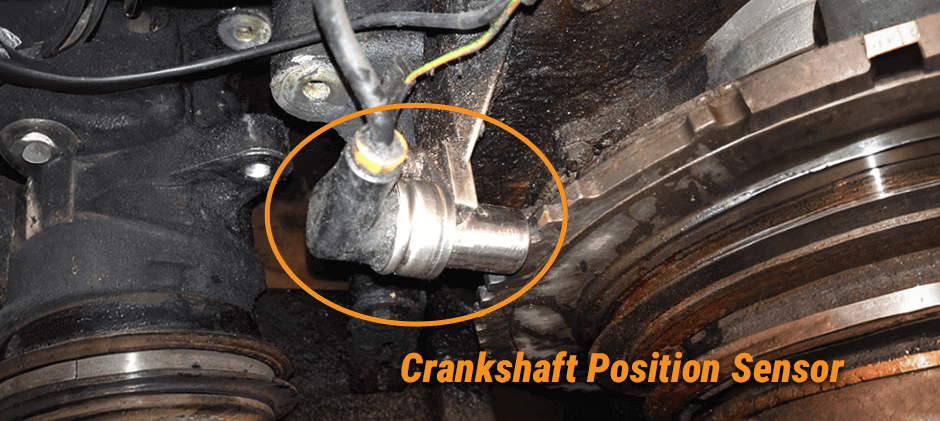

The crankshaft connects to the piston. As the piston moves up and down, the crankshaft spins right along with it. This spinning power drives the machine’s tracks, turns the wheels, and keeps the hydraulic system running smoothly. The crankshaft position sensor (CKP) does what its name suggests: it measures how fast the crankshaft is turning (the RPM) and where it is turning. It works simply — reads information from a gear (or grooved wheel) that rotates with the crankshaft and generates a corresponding signal. This sensor is generally installed at the front or bottom of the engine block.

This signal is transmitted directly to the Engine Control Module (ECM), which is equivalent to the engine’s “master computer”. ECM relies on this data to control key components, the most important of which is the timing of fuel injection. If the crankshaft position sensor does not send a clear signal, the ECM does not know when to inject oil. In this way, the engine will either spin or stumble or simply won’t start.

Bad Crankshaft Position Sensor Symptoms

The CKP sensor’s data is vital for your engine to run. If your heavy equipment has any of these bad crankshaft position sensor symptoms, you need to pay attention.

Check Engine Light On

Modern heavy equipment has smart onboard diagnostics. The ECM keeps an eye on the signal from the crankshaft position sensor nonstop. If the signal is lost, all over the place, or not what the ECM expects, it’ll light up the check engine light on your dashboard right away. When the diagnostic scanner is connected, a saved fault code is usually seen in the engine control module (ECM). Common codes related to crankshaft position sensors (CKP) include:

- P0335: Crankshaft Position Sensor “A” Circuit Malfunction

- P0336: Crankshaft Position Sensor “A” Circuit Range/Performance

These codes are a direct pointer to the sensor or its wiring as the source of the problem.

Engine Will Not Start or is Hard to Start

When turning the key, if the engine control module (ECM) cannot receive the signal from the crankshaft position sensor (CKP), it does not know whether the engine is rotating. The ECM does not direct injector operation for safety and control purposes. The result is the engine just keeps idling and won’t start because there’s no fuel going in.

Sometimes, instead of the sensor being completely broken, the signal fluctuates. This makes it difficult to start the engine. You have to play for several seconds or more before it barely starts. This problem is often more pronounced when cold weather and can become more severe over time.

Engine Stalling or Cutting Out

A faulty sensor can also make the engine cut out suddenly. That’s super dangerous for heavy equipment. The sensor might work okay at first, but then its signal just drops. Maybe from an internal problem or a loose wire. As soon as the ECM loses that important data, it stops sending fuel to the engine. And the engine shuts off right away.

This stalling can happen when the machine is idling. Or even worse, when it’s working hard, like lifting a heavy bucket of stuff or driving up a hill. An engine that cuts out with no warning isn’t just a hassle. It’s a big safety risk for the operator and anyone around.

Rough Running, Misfiring, and Loss of Power

If the CKP sensor’s signal isn’t totally gone but is spotty or glitchy, the ECM gets bad data. It might mix up how fast the engine’s going or where its parts are, so it sprays fuel at the wrong time. That causes a bunch of performance problems:

- Rough idle: The engine might shake or vibrate pretty bad when it’s just sitting.

- Engine misfires: You might feel the engine stumble or lag. Especially when you hit the gas to use the hydraulics or move the machine.

- Loss of power: With fuel going in at the wrong time, the engine can’t put out its full power. The machine’ll feel sluggish and struggle with jobs that used to be easy.

A misfiring engine isn’t just a performance issue. In modern diesel engines, it can set off a chain of problems, like incomplete burning of fuel. That can quickly clog up expensive after-treatment parts, like the Diesel Particulate Filter (DPF).

Increased Fuel Consumption

If the engine isn’t running right, it’ll definitely burn more fuel. When a bad CKP sensor messes up fuel timing and makes the engine run rough, the combustion process gets super inefficient. The ECM might try to fix the poor performance by spraying more fuel—but that just wastes it. For owners who operate the machine themselves or fleet managers, a sudden drop in fuel efficiency hits hard. These machines run 8-10 hours a day, so that extra fuel use adds up to high, unnecessary costs for operations.

How to Diagnose a Crankshaft Position Sensor?

If your equipment’s acting up with these issues, follow these steps to figure out what’s wrong. We still suggest getting a pro tech to handle it. But if you know the basic check process first, you can explain the problem way better to them.

Do a Scan Test

Hook a diagnostic scan tool to the machine’s data port. Pull up any active or stored error codes (DTCs). Codes like P0335 or P0336 usually mean the crankshaft position sensor (CKP) circuit is having trouble.

Check Live Data

A good scan tool shows real-time info from the engine’s sensors. When you’re cranking the engine, the tech can watch the “Engine RPM” reading. If it says 0 but the engine’s clearly turning? The CKP sensor isn’t sending a signal. If the RPM jumps all over the place? The sensor’s probably going bad.

Take a Visual Inspection

Check the sensor and its wires for obvious damage. Look for melted plastic, frayed or broken wires, or rust on the connector pins. Also, make sure the sensor is tight. And double-check the gap between the sensor tip and the signal wheel, follow what the manufacturer says.

Test with a Multimeter

For a sure answer, use a digital multimeter (DMM). How you test it depends on the sensor type:

- 2-Wire Variable Reluctance (VR) Sensor: These make their own AC voltage. Disconnect the sensor and check its internal resistance. Then, while cranking the engine, measure the AC voltage it puts out. A good sensor should make a small but steady AC voltage—one that gets stronger as the engine speeds up.

- 3-Wire Hall-Effect Sensor: The ECM gives this power, and it sends a digital square wave signal. Keep the connector plugged in, turn the key on, and the tech will test the pins. You should see power (usually 5V or 12V), a good ground, and a signal wire. When you crank the engine, the signal wire’s voltage should flip fast between 0V and the supply voltage.

What Causes Damage to Your Crankshaft Sensor?

Crankshaft position sensors usually fail for these common reasons:

- Extreme Heat: Engine bays get really hot. Modern machines with emission systems get even hotter. Over time, that heat can break the sensor’s plastic case. Or mess up its inside parts. Eventually, the sensor stops working.

- Vibration and Physical Damage: Heavy equipment vibrates a lot—especially when it’s working. Over time, the shaking can wear out the wiring harness. It might even break. The plug can get loose, too. If the equipment works on construction sites or farms a lot, stones or mud might hit the sensor or wires. That can damage them.

- Contamination: Oil, fuel, or hydraulic fluid leaks can get into the sensor’s connector. That makes rust and ruins the electrical signal. Dirt and grime can also build up on the sensor tip, which might stop it from reading the signal wheel correctly.

Conclusion

Don’t ignore the crankshaft position sensor symptoms above. If the technician has confirmed that there is a problem with the crankshaft position sensor, it is best to replace it as soon as possible. You can find the accessories you need at FridayParts. The crankshafts and related components we provide are quality-checked and perform as reliably as the original parts. You also don’t have to worry about choosing the wrong model. Just enter the device information on our website and you can quickly find matching parts. Now take a look at our products and choose a crankshaft position sensor that is suitable for your equipment.