The primordial puissance of an excavator doth verily hinge upon the implement affixed unto the terminus of its arm. Shouldst thou elect an errant tool, not only shall thine efficacy of toil be diminished, but also fuel, time, and lucre shall be squandered. Each bucket upon the market is contrived for a most singular task, whereby the multitude thereof rendereth the beholder bewildered. This present treatise shall aid thee in unraveling such perplexity. We shall discourse upon ten diverse excavator buckets of common employ, expound their utility, peculiar essence, and designated function, that thou mayest assuredly select the bucket most befitting, to magnify unto the utmost the efficiency of thy machine upon whatsoever worksite it be engaged.

1. Digging Bucket

This is the all-purpose, standard-issue bucket that most people picture when they think of an excavator. It’s the jack-of-all-trades in the bucket world, designed for general digging and material handling tasks.

- Key Features: It has a good balance between width and capacity, with short, sharp teeth along the cutting edge. This design allows it to break through moderately compacted soil and scoop material effectively.

- Best Applications: The digging bucket is your go-to for a wide range of tasks, including trenching for foundations, general excavation, and loading trucks with soil or gravel. It’s the default choice for most earthmoving projects.

2. Rock Bucket

When the job gets tough, the rock bucket gets going. This is a heavy-duty, reinforced version of a digging bucket, specifically engineered to handle abrasive and high-impact materials that would destroy a standard bucket.

- Key Features: It uses high-strength, abrasion-resistant steel in its construction. The profile is often narrower and more V-shaped to concentrate the excavator’s breakout force. The effectiveness of a rock bucket comes down to its V-shaped profile and, most importantly, the quality of its bucket tooth setup. These teeth are longer, sharper, and forged from extremely hard steel to penetrate solid rock.

- Best Applications: Such a bucket is of indispensable necessity for the laborers within quarrying, for the fracturing and the loading of blasted stones, for the excavation of the most unyielding shale, as well as for surmounting those obdurate rocky grounds which a bucket of ordinary digging may by no means subdue.

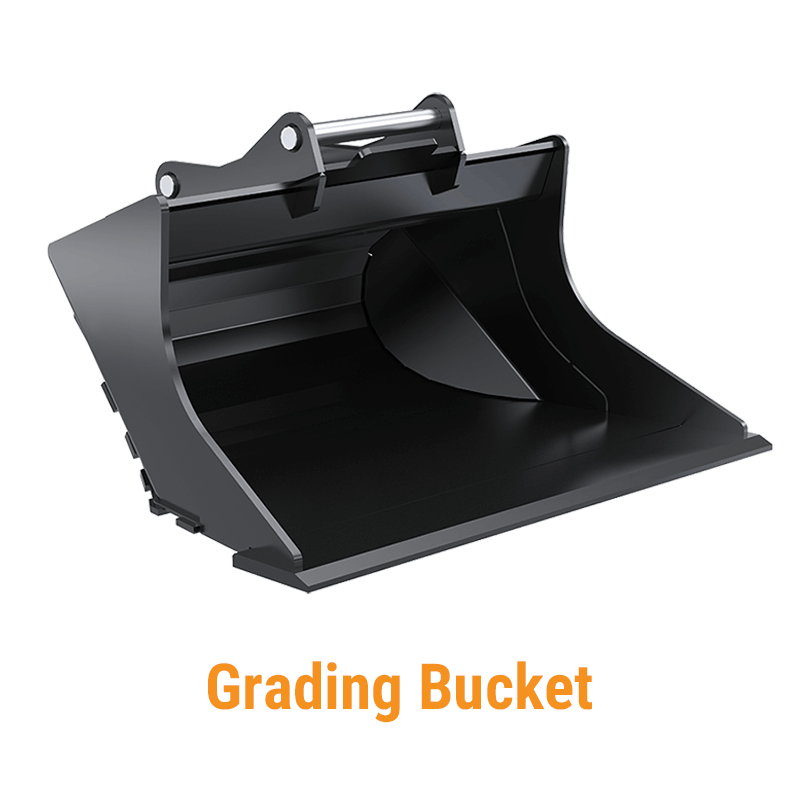

3. Grading Bucket (or Clean-up Bucket)

The grading bucket, also called a finishing or ditching bucket, is not meant for aggressive digging. Its purpose is all about precision and creating a smooth, level surface.

- Key Features: The most notable features are its wide profile and a long, flat cutting edge with no teeth. It also has a shallower depth than a digging bucket. Many models have holes in the back to allow water to drain out when cleaning ditches.

- Best Applications: This bucket serves final finishing work. Operators use it to level ground, grade slopes, spread topsoil, backfill trenches, and clean out ditches. The flat edge leaves a clean, professional finish.

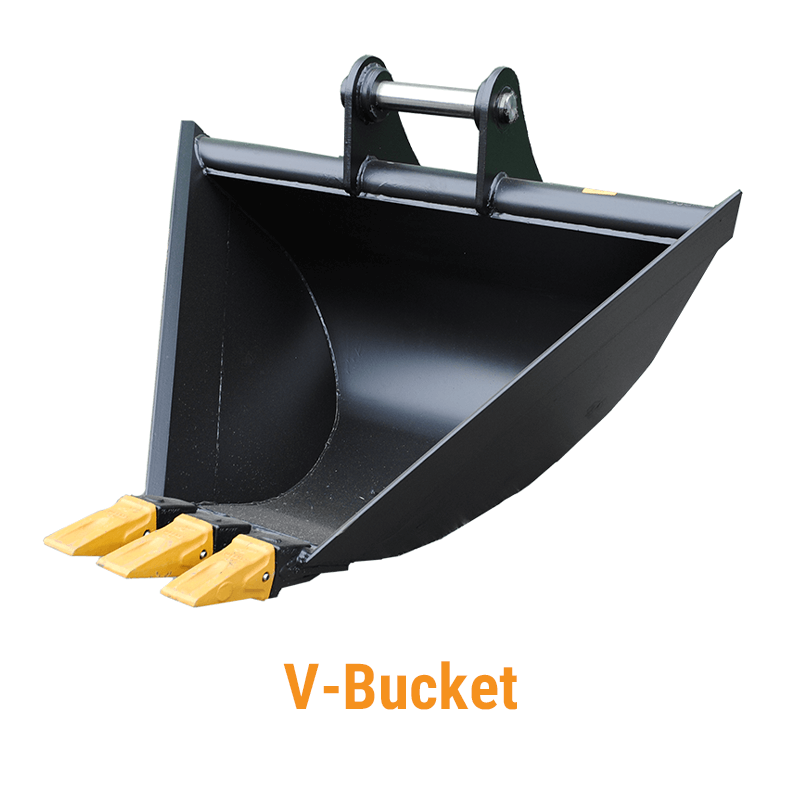

4. V-Bucket

As the name suggests, this bucket has a distinct “V” shape. This specialized tool serves one primary purpose: digging clean, precisely angled trenches in a single pass.

- Key Features: The triangular design makes it capable of excavating a side-inclining V-shaped trench, compared with the vertical wall trench; this kind of trench is less likely to collapse. V-shaped buckets provide multiple angles (for example, 30 degrees, 45 degrees, 60 degrees), in order to satisfy different project demands.

- Best Applications: The V-shaped buckets are very suitable for laying utility lines, pipelines, and cables that need a specific trench contour. People also frequently use it in agricultural and construction environments to excavate a drainage ditch.

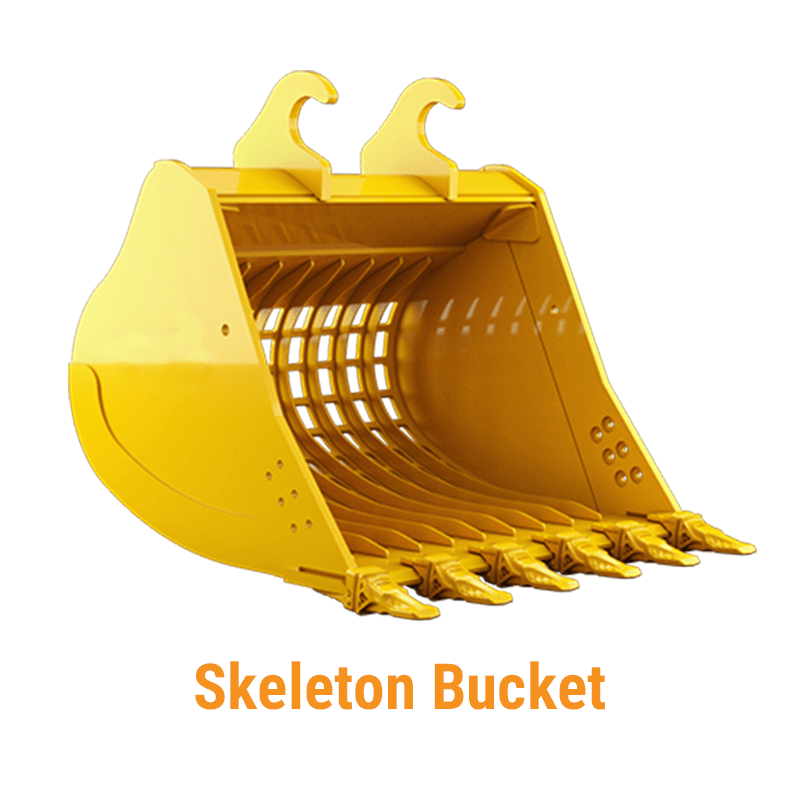

5. Skeleton Bucket

The skeleton bucket is a clever combination of a digging bucket and a sieve. It digs and sorts material at the same time, separating large objects from fine soil.

- Key Features: Instead of a solid back, the skeleton bucket has a grid of heavy-duty ribs or tines. As the bucket scoops material, smaller particles like dirt, sand, and gravel fall through the gaps, leaving only the larger rocks, demolition debris, or roots inside.

- Best Applications: This is incredibly efficient for site clearing, demolition projects, and quarry work. It allows you to separate valuable topsoil from unwanted rubble or to sort different sizes of rock without needing a separate screening plant.

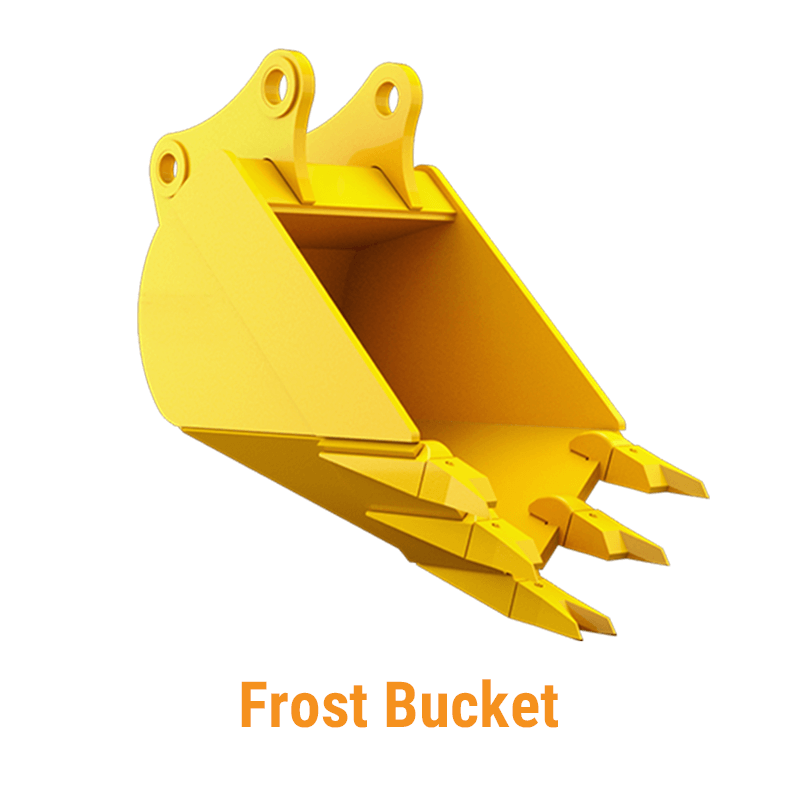

6. Frost Bucket

When the ground freezes solid or you face exceptionally hard, compacted rock, even a standard rock bucket might not be enough. The frost buckets are the most aggressive digging tool in the arsenal.

- Key Features: It features an extra-tough build and a very narrow profile that focuses all of the machine’s power onto a single point. Its defining feature is a large, singular ripper tooth in the center, often supplemented by smaller side teeth. This “tiger tooth” acts like a pickaxe to shatter frozen ground or pry apart stratified rock. The immense force required for these tasks puts significant strain not just on the bucket but on the entire machine, especially the undercarriage parts.

- Best Applications: This is a specialty tool for extreme conditions. It excavates permafrost, breaks through thick ice, and tackles the hardest rock formations.

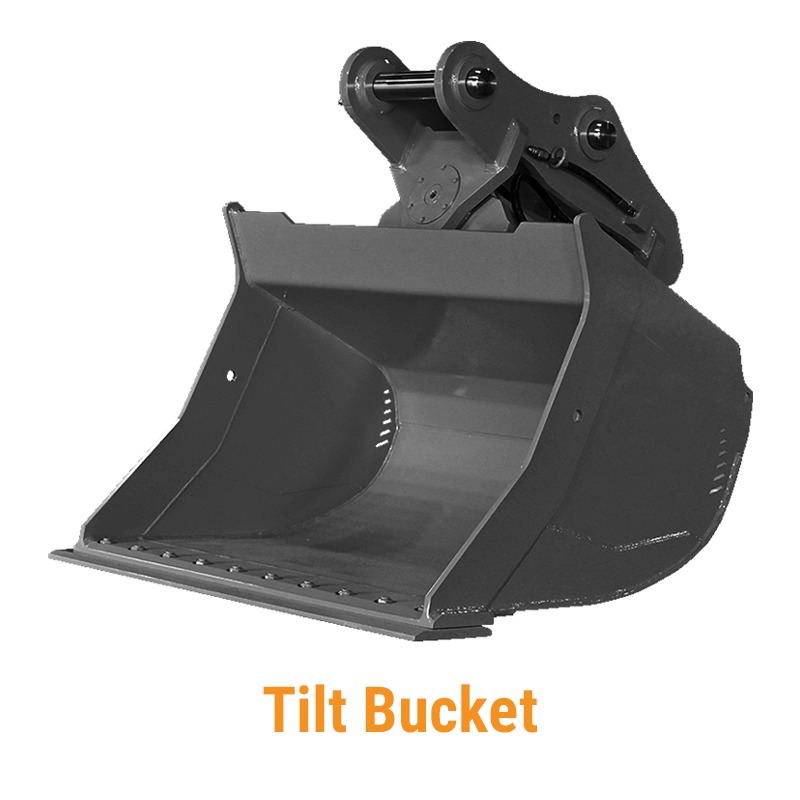

7. Tilt Bucket

The tilt bucket takes the functionality of a grading bucket and adds a new dimension of versatility. The operator can hydraulically angle it from the cab.

- Key Features: A hydraulic cylinder (or cylinders) allows the bucket to tilt up to 45 degrees in either direction, independent of the excavator’s arm. This lets the operator create complex slopes and contours without constantly repositioning the entire machine.

- Best Applications: It is the ultimate tool for landscaping, creating complex ditch profiles, grading on uneven terrain, and shaping banks. The ability to change the angle on the fly dramatically increases speed and precision.

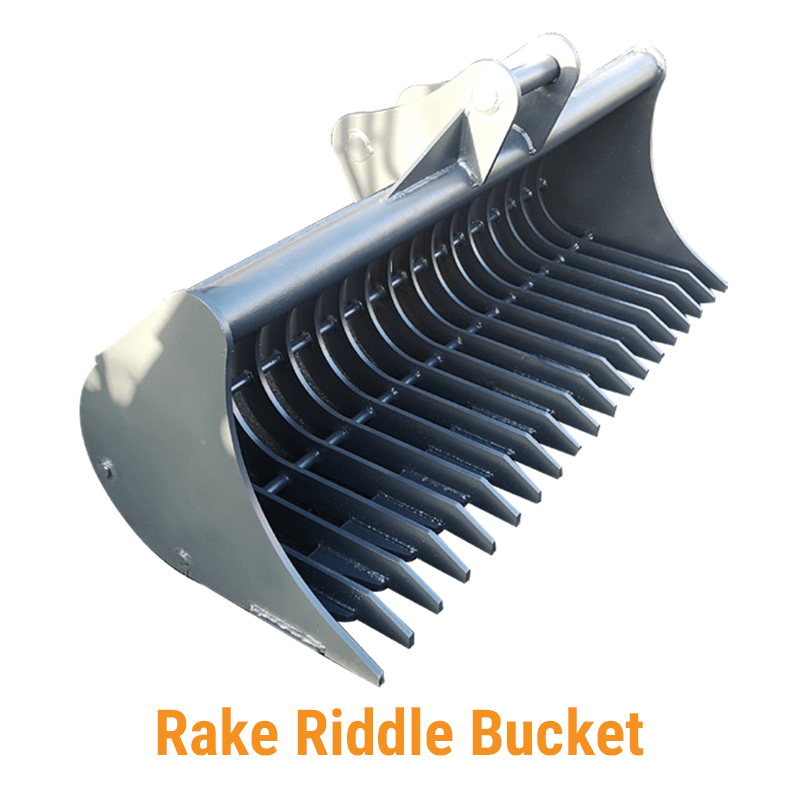

8. Rake Riddle Bucket

While similar in concept to a skeleton bucket, the rake riddle bucket focuses more on combing and raking than on aggressive digging and sorting.

- Key Features: It has long, widely spaced tines that resemble a heavy-duty garden rake. It has a much shallower profile and less carrying capacity than a skeleton bucket.

- Best Applications: Its primary use is for land clearing. The tines effectively rake through topsoil to remove roots, stumps, brush, and other vegetation while leaving the valuable soil behind. It’s a favorite tool for agricultural land prep and forestry site cleanup.

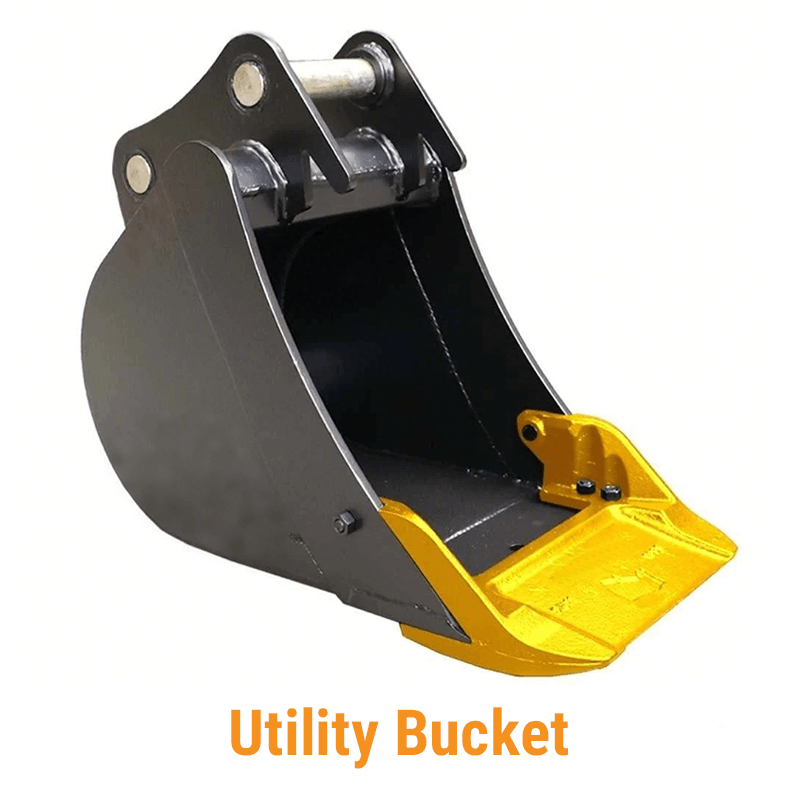

9. Utility Bucket

Safety is the number one priority when digging in areas with buried infrastructure. The utility buckets are designed specifically to minimize the risk of damaging underground pipes and cables.

- Key Features: The defining characteristic is its smooth, rounded, toothless cutting edge. This design prevents the buckets from snagging, piercing, or tearing utility lines during excavation. The structure is still strong, but it’s designed to push lines aside rather than cut them.

- Best Applications: This is the only bucket that should be used for digging around known utility lines, such as water mains, gas lines, and fiber-optic cables. It is essential for urban and residential excavation projects.

10. Micro Trenching Bucket

This is an extremely narrow, deep bucket designed for creating small, precise trenches with minimal ground disturbance.

- Key Features: It is often no wider than a few inches but can dig several feet deep. Some versions are designed as a “wheel” that cuts a continuous, narrow slot in the ground.

- Best Applications: Its primary use is for installing fiber-optic cables, small-diameter irrigation lines, and other utilities that require a very narrow trench. This method is much faster and requires significantly less backfill material than digging a wider trench with a standard bucket.

Equip Your Machine for Maximum Productivity

To elect a bucket most befitting unto an excavator may verily conduce to the optimization of the whole laboring process, thereby augmenting swiftness, fortification of safety, and the enlargement of profit. Yet the appendages of the bucket—such as the teeth and the cutting edge—belong amongst the consumable parts, which must often be inspected and replaced. With this in mind, Friday Parts has you covered. We offer a wide selection of durable excavator buckets, teeth, and other parts at affordable prices, ensuring you find the right part to get the job done efficiently. Browse directly on our product page.