When you start the excavator as usual and prepare for a day’s work, you suddenly hear abnormal noise from the engine, unstable RPMs, and even occasional flameout. Do you worry whether the entire fuel system has been seriously damaged? This situation often happens to our customers. According to the experience of our maintenance personnel, if you find no leakage or obvious damage in the fuel pipeline, then the problem is likely to be a clogged fuel filter.

In the early stages, fuel filter blockages are hard to notice. But over time, restricted fuel flow can seriously affect engine performance and even cause long-term damage. That’s why it’s crucial to recognize the symptoms of a failing fuel filter early. In this article, we’ll break down the warning signs and offer practical tips to help you prevent costly repairs.

Key Takeaways

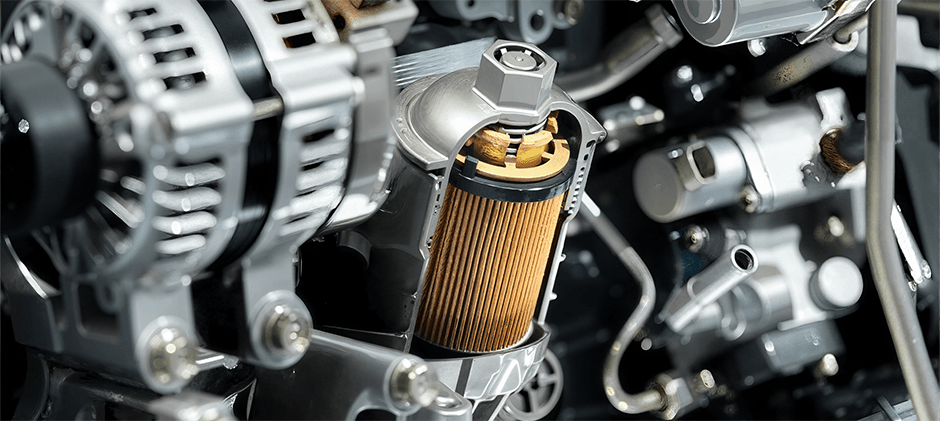

- A fuel filter’s main job is to protect your engine, but when it’s full, it starves your engine of clean fuel.

- The most common signs are a loss of power under load, difficulty starting, and a rough, unstable idle.

- Ignoring these symptoms can lead to the destruction of extremely expensive fuel injectors and high-pressure fuel pumps.

- Regularly replacing your fuel filter is the cheapest and most effective insurance policy for your engine’s fuel system.

Why Does the Fuel Filter Get Clogged?

Unlike cars that rely on clean, high-grade fuel, heavy equipment often uses lower-quality or impure diesel to reduce operating costs. While this might seem economical in the short term, it increases the risk of contamination, especially when machines operate in harsh environments like construction sites, farms, or quarries. In these conditions, your fuel filter becomes the engine’s most critical line of defense.

Fuel filters in heavy equipment can become clogged due to a variety of common issues. Dust and debris from dirty fuel nozzles or job sites can enter the tank during refueling. Water contamination—from condensation inside the tank or unsealed fuel storage—can encourage microbial growth, leading to thick diesel sludge that quickly overwhelms the filter. Rust particles from aging tanks only add to the problem. As these contaminants build up, the filter becomes saturated, restricting fuel flow and causing engine trouble. Identifying these causes early can help you avoid serious damage and save at least $100 or more in repair costs.

10 Symptoms of a Clogged Fuel Filter

When your engine isn’t getting enough fuel because of a clogged fuel filter, your machine will start showing signs, sometimes subtle, sometimes obvious. These early warnings are easy to miss, but ignoring them could lead to serious engine damage and costly downtime. Based on insights from experienced maintenance technicians, we’ve put together 10 common symptoms to help you quickly spot fuel filter issues before they turn into bigger problems.

1. Loss of Power Under Load

Your machine runs fine when idling or driving on flat terrain, but feels weak or bogs down when lifting heavy loads or climbing slopes. This happens because a clogged fuel filter restricts fuel flow, starving the engine during high-demand situations.

2. Difficulty Starting the Engine

If the engine cranks for a long time or fails to start—especially in cold weather—it could be due to a severely blocked fuel filter preventing the fuel system from building enough pressure for ignition.

3. Rough or Unstable Idle

An uneven idle, with the engine surging or dipping unexpectedly, may indicate inconsistent fuel delivery caused by a partially blocked filter. In severe cases, the engine may even stall at idle.

4. Engine Stalling

The engine may start and run briefly but then stall, especially under light load or after moving. This suggests the filter is so clogged it only allows minimal fuel through—enough to start, but not to sustain operation.

5. Increased Black Smoke from the Exhaust

Excess black smoke during acceleration or heavy work often signals incomplete combustion due to poor fuel flow, which disrupts the engine’s air-fuel ratio.

6. Sputtering or Hesitation During Acceleration

If your machine hesitates or sputters when you accelerate, it’s likely that the fuel filter can’t keep up with the sudden increase in fuel demand, causing momentary fuel starvation.

7. Check Engine Light Illumination

Modern equipment uses sensors to monitor fuel pressure. When pressure drops due to a clogged filter, the system triggers a warning light or fault code on your dashboard.

8. Shortened Fuel Filter Life

If you’re replacing fuel filters more often than expected, it’s a sign of excessive contamination—possibly from dirty storage tanks—causing premature clogging.

9. Noisy or Failing Fuel Pump

A whining or strained sound from the lift pump suggests it’s working too hard to push fuel through a blockage. This added stress can lead to pump overheating or failure.

10. Visible Contaminants in the Filter Bowl

If your filter has a clear sediment bowl and you see water, sludge, or rust-like particles, it’s a clear sign your fuel is contaminated and the filter is either clogged or nearing saturation.

Spotting these warning signs early can make all the difference. Staying on top of fuel filter maintenance helps keep your machine running smoothly and ensures you’re ready for whatever the job throws your way.

What Other Components Might Be Affected?

Continuing to operate a machine with a clogged fuel filter is a costly mistake. A $50 filter is not worth risking a $5,000 repair bill. The filter itself is cheap to maintain, but its damage can have serious consequences for other critical equipment.

- Fuel Injectors: This is the biggest risk. Modern high-pressure common rail (HPCR) systems use injectors with incredibly fine tolerances. If the filter is clogged, the fuel pump can be strained to the point where it creates enough pressure to force tiny abrasive particles through the filter media. These particles then act like sandblasters, destroying the delicate nozzles inside the injectors, leading to poor performance and repairs that can cost thousands of dollars.

- High-Pressure Fuel Pump: Just like the lift pump, the main high-pressure fuel pump is lubricated and cooled by the fuel that flows through it. When that flow is restricted, the pump can overheat and fail prematurely. This is another extremely expensive component to replace.

- The Engine Itself: In the long run, running on a lean fuel mixture can lead to higher combustion temperatures, putting extra stress on pistons, rings, and valves, potentially shortening the overall life of your engine.

How to Check a Clogged Fuel Filter?

Checking for fuel filter blockage is not complicated. There are a few simple ways to check—no advanced tools required. Just be sure to work safely: diesel fuel is flammable and can irritate your skin, so wear gloves and eye protection, and always work in a well-ventilated area.

1. Do a Visual Check

Start with the easiest method. If your machine has a fuel filter with a clear bowl, take a close look. Water settles at the bottom and looks like a separate, clear layer. You might also see dark sludge, rust particles, or black specks—these are signs your fuel is contaminated and the filter is likely clogged.

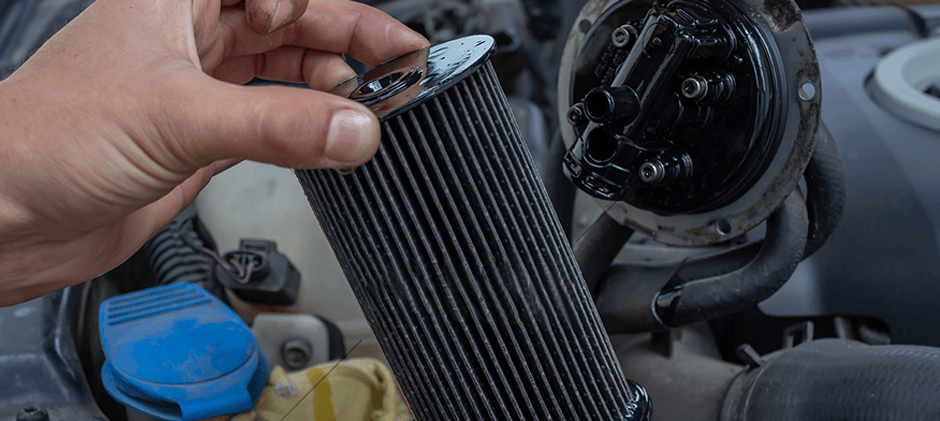

2. Try the Blow Test (For Removed Filters)

Remove the old filter and let it drain. Then try blowing into the inlet port. If air passes through easily, it’s probably fine. If it’s hard or impossible to blow through, the filter is likely blocked, and the manufacturer needs to be replaced.

3. Fuel Pressure Test (For Advanced Users)

If you have access to a fuel pressure gauge, you can get a precise reading. Low fuel pressure compared to your machine’s specs often points to a restriction—and a clogged filter is the most common cause.

In most cases, a dirty fuel filter should be replaced rather than cleaned. If you’re curious about cleaning methods, check out our related post: How to Clean a Diesel Fuel Filter. But when in doubt, swap it out.

How Often Should You Change The Fuel Filter?

There is no single answer for all machines; the replacement interval depends on your equipment’s manufacturer, your working conditions, and the quality of your fuel.

- Check Your Operator’s Manual: This is the most important rule. Your manual will specify the recommended change interval in operating hours.

- Typical Intervals: For most modern heavy equipment, the standard interval is to replace the fuel filter every 300-500 hours of service, often at the same time as the engine oil change. Some manufacturers may recommend a 250-hour interval for the primary filter/water separator.

- Adjust for Conditions: If you work in extremely dusty environments or know you have issues with fuel quality, you should shorten this interval. It’s better to change a filter a little too early than a day too late.

Conclusion

The humble fuel filter is a small, inexpensive part that plays a massive role in the health and performance of your heavy machinery. The symptoms of a clogged fuel filter—from power loss to hard starting—are your engine’s way of asking for help. Ignoring these signs is a direct path to reduced productivity, unplanned downtime, and potentially catastrophic damage to your fuel system. Regular, preventative replacement is one of the smartest, most cost-effective maintenance procedures you can perform.

If you’re dealing with a clogged fuel filter, FridayParts has you covered. We offer high-quality, affordable fuel filters compatible with top brands like Caterpillar, Komatsu, and John Deere—so you can get back to work fast.